Ignition

“The problem of problems.” Karl Benz 1880

At the dawn of internal

combustion motors many strange and unusual devices were invented to provide the

ignition needed to make the motors work.

Lenoir, the original inventor

of stationary gas motors way back in 1860 used the first spark plug fired by a

battery buzzer coil device. Otto used a tiny trap door with a

chamber for a bit of burning coal gas to slide over a hole in the top of the

combustion chamber but found that it was a poor idea.. Karl Benz

used a variation of the battery vibrator ignition on the first auto and was so

frustrated with the problems of reliability that he provided the quote about

ignition in the subtitle above..

Then a magnetic oscillating

magneto device using an upgraded primitive spark plug was used.. (the

great scientist Siemens of Germany invented the swinging twin T magneto)

Daimler’s group came up with the strange idea of a heated ceramic tube opening

into the combustion chamber. This worked well at the time and started easily.

But the external fires needed to keep the tubes hot were a dangerous

design.

Both Count Zeppelin (who

wanted to use Daimler motors in his hydrogen airships) and Emil Jellinek

(Daimlers first and best salesman, racing enthusiast, and father of Mercedes

Jellinek whom the Mercedes auto is named after) insisted that magneto ignition

be used.

Zeppelin because of the fire

hazard with the hydrogen in the airships and Jellinek because he had

experienced so many serious fires in his Daimlers when he was racing..

Robert Bosch enters at this

point as the maker of most of the oscillating magneto low voltage ignition

systems used.. Then one of Bosch’s employees came up with the high

voltage rotary magneto and that became the standard.

Daimler always resented Bosch

and was angry that his beloved hot tube ignition was discarded so quickly.

But.. There is

always a but. The magneto ignition worked well at high speeds when

the motor was running but it was very difficult to start. Since the

magnets of the day were weak and lost their magnetism slowly and the amount of

spark was directly dependent on crankshaft speed hand crank starting a magneto

motor was difficult at best and almost impossible in the cold or wet..

The early racing cars carried

a mechanic to adjust timing and mixture and operate the fuel pump while the

race was going on. But a big reason for the extra man was the “Run and

Bump” starting used. The driver and mechanic would run along beside

the car pushing it as fast as possible. Then they would jump in and the

driver would put the car in gear and let out the clutch spinning the motor fast

enough to get the magneto working.

The vibrator shower of sparks

battery ignition (which had been around for many years) on the other hand was

easy to start but very poor at higher rpm’s. (in those days 1800 rpm was

considered high) As a result many manufacturers began to use both

battery igniton for starting and then switch to magneto ignition for

running.. Complicated, expensive, and the dry cell batteries had to

be replaced often. The magnetos needed recharging of their magnets

periodically as well.

Then in about 1906 one of the

greatest inventors in history began working on an improved battery

ignition. Charles Franklin Kettering working with his small group in a

converted barn in Ohio invented the standard ignition system used from 1909 to

the present.. The Kettering ignition.

This ignition provided a

single spark at the right moment and had the precision and reliability needed

to make automobiles more than a toy or curiosity.

This is how the Kettering

system works.

The electrical current from

the battery first goes through a resistor to limit current when the points are

closed and the motor is not running and to provide a better shape to the pulse

of electricity generated by the coil. The resistor is bypassed when using

the electric starter because the voltage drop from the high current used by the

starter reduces the spark. Then the current goes through the primary

winding of the coil. This is the low voltage high current side of the

coil windings.

Then it reaches the

points. They are tungsten switch contacts inside the distributor opened

by a cam which rotates at half the speed of the crankshaft. The

points are normally closed allowing current to flow to the coil primary

winding. This period when the points are closed is called the dwell

time.

When the points open from the

passing bump on the cam the magnetic field within the coil collapses very

quickly generating a high voltage pulse in the secondary winding of the

coil. There is a serious problem with the points arcing when they open

and a capacitor (used to be called condensor) is in parallel with them to

absorb the voltage spike that would cause them to arc and burn out quickly.

The high voltage pulse in the

secondary winding of the coil is led through the rotor to the proper contact on

the distributor cap for the cylinder which is firing. Then through

specially insulated high voltage wire to the sparkplug. At the sparkplug

a spark jumps the gap between the outer ground electrode and the center

positive electrode lighting the fuel/air mixture at the proper instant.

The timing of the spark is

critical for proper operation of the motor and at first it was the

responsibility of the driver. The ignition advance/retard was manually

done with a lever on the steering column.. Retard for starting

and advance for more power when running but listen for pinging and retard as

necessary.. Quite an interactive situation.. Drivers

were much busier in the early days..

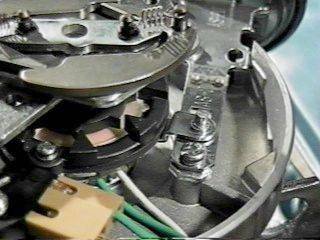

Then several inventions took this responsibility away from the driver and made it part of the mechanism. Advancing the ignition as rpm increased compensated for the amount of time it took for the mixture to burn. For starting the spark would be retarded automatically and using springs and centrifugal weights the advance would increase with rpm. See picture below for the weights and springs of the advance mechanism.

Then it was found that when

driving at low speeds with the throttle almost shut the reduced filling of the

cylinder caused the mixture to burn more slowly than at full throttle. So

an additional advance mechanism was invented that had a vacuum diaphram and

spring to advance the timing at high vacuum conditions when the throttle was

almost closed and the motor was running at much reduced power.

This combination served very

well to make the ignition function so smoothly and unobtrusively as to be

ignored until a failure from lack of maintenance occurred.

The weakest link in the chain

of reliability was the points. After that the spark

plugs.. The points were only capable of about 5-10 thousand

miles of operation before they needed adjustment or replacement.

The tiny spark every time they opened eventually destroyed them..

Consider that in 5000 miles on a v8 motor that is about fifty million nasty

little sparks eating away at the tungsten contacts..

As the points were

disintegrating it would cause the gap to widen and the dwell time to

increase. This would increase the current beyond what was needed to

generate the maximum magnetic field in the coil causing it to heat up and

reduce it’s output. Also with the larger gap the timing would

be retarded, sometimes enough to cause overheating in the summer..

Too little or too much gap both could cause problems.

Meanwhile in the motor the

spark plugs were losing metal from the sparking and the gap would widen and the

electrodes would be rounded both causing more voltage to be needed to fire the

mixture properly..

Then about 45 or 50 years

after Kettering’s invention (a long time for technology to stay the same) a

major improvement to his ignition system was made.

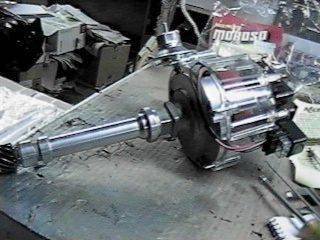

Others had similar devices

but I will discuss the GM HEI Ignition system. This concept brought

Kettering’s 19th century design into the 20th century.

The points were discarded and

replaced by a magnetic reluctor. This is a star shaped piece of

metal rotating within a circular magnetic pole with matching points directed

inward toward the center. See picture below for a view of the

reluctor and sensor pole in the HEI.

The change in magnetic flux in the reluctor/sensor assembly was detected by a winding at the base of the sensor and provided an input to the transistorized switching circuit in the ignition module. The output of the ignition module went to a coil similar to the Kettering design but GM chose to package the coil in the top of the distributor cap to make the ignition a one piece unit.

There was no need for

the capacitor to protect points but one was installed to prevent interference

to the car radio..

The reluctor/sensor/switch module arrangement took the place of the unreliable points and could go for hundreds of thousands of miles without problems.. A most impressive advance.

See picture above for a look at the complete integrated

system. And picture below shows a schematic of the HEI system.

The voltage available from

the HEI is much greater than the old points style system. About 35-40

thousand volts compared to 20-25 thousand from the points

stystem. This allowed the sparkplugs to run a larger gap and be

less sensitive to wear and fouling. A superior system in every way except

one. If you are ever shocked by the high voltage from a HEI system you

will never forget it.

The GM HEI is a fine reliable

system for stock autos but.. (another one of them)

It does require some changes

to make it suitable for high performance use. Changes to make the

timing more precise, to make the advance curve provide maximum horsepower, and

to allow higher rpm operation.

These issues will be

addressed in my next article..

Rick Draganowski

Gold Beach, Oregon