Subject: Return of Rustpuppy report 96

Date: Wednesday,

February 14, 2001 5:57 PM

Had a

bad week but pressed on with the Nova work regardless..

The

first order of business was to get the seat out of ol’ Rustpuppy. Since I have the mounts modified (moved

back about 7.5”) and the shifter locking the position of the seat from moving

forward on the slides getting the two rear bolts out involved a bit of

acrobatic standing on head in back seat while scratching around under the seat

with wrenches. But eventually

skill and science prevailed and the seat was out.. (ror96-1.jpg and ror96-2.jpg)

The seat

assembly weighs 84 lbs.. More than

I thought..

The

nasty looking grot all about on the floor is mostly just dirt built up over the

last 8 years.. (and a bit of

surface rust..) Ror96-3.jpg

shows the brackets which allow the seat to go back far enough to fit my long

fat ol’ legs..

Ror96-4.jpg and ror96-5.jpg show the special alloy

brackets I made back in 1993 to move the seat belt reels back so they can be

used properly with seat so far back..

I have never been happy with these brackets as they really require a

second mounting point to prevent them bending the floor and pulling up in case

of a serious crash. Having

the seat out allows this omission to be corrected..

The next

picture shows the seat out and ready to be properly hog-ringed up to put the

seat covers from Whitney on correctly.

(ror96-6.jpg)

Remember

back when I was doing the rear axle swap and I was bitching cause I lost track

of the metal bar used by GM to hold the right rear emergency brake cable in the

right position? Well it

showed up imbedded in the lawn right where I dropped it. The picture was taking after it was

moved so it is quite visible.

Before it was just barely peeking out of the grass.. I cleaned up the rust and gave it a

couple coats of the self-etching primer..

Looking much better..

(ror96-7.jpg and ror96-8.jpg)

More to

come..

Rick

Draganowski

Subject: Return of Rustpuppy report 97

Date: Friday,

February 16, 2001 5:32 PM

As I

mentioned in ror96 the brackets, which mount the seat belt reels, were not good

enough. I attacked this issue

first.

First I

scratched around under the car looking for a good place to mount a rear

brace. There was a clear space in

the reinforcing plate, which mounts the spring bracket on each side so a 3/8”

hole appeared in them. It

would take a lot to pull through there.

Then I

pulled the brackets, cleaned them up and milled the corners off to allow a

clear shot for the rear braces.

(ror97-1.jpg) You can see

the hole in the floor in this pic.

Then I burst into a frenzy of cutting, grinding, drilling,

and hammering to fabricate two rear braces. They are 1/8” by 1” steel with a nice coat of the self

etching primer.. Ror97-3.jpg shows

the drivers side brace in position..

Then I

wanted to do something about the naked battery cable running through Rustpuppy.

(which is live all the time and not really too safe) The front is threaded through a piece of conduit in the hole

in the floor to protect it from the edges of the hole. (ror97-4.jpg)

The rear just leaks in through one of the big holes

leading to the trunk. (ror97-5.jpg)

NHRA does not like these big holes I understand..

My

solution for the battery cable is based on a piece of ½” flexible conduit. (called it BX cable when I was a kid

workin with my Dad..) Currently the battery cable was protected under the hood

with a piece of split heater hose and some aluminum tape.. (ror97-7.jpg)

After

drilling out a 1” hole in the firewall I removed the battery terminal (breaking

it) and threaded the cable through the flexible conduit. Easier said than done as it took a lot

of fooling around and all my strength to slide it through there by pushing..

Ror97-8.jpg,

ror97-10,jpg, ror97-11.jpg, and ror97-12.jpg show the new improved battery

cable system.. Looks good to

me.. You can see the broken

terminal in ror97-9.jpg.. I

had a spare hangin on the shop wall because I know these cheapies are one-shot

jobs..

Next I

will be cleaning up the interior and doing something about them big trunk

holes..

More to

come..

Rick

Draganowski

Subject: Return of Rustpuppy report 98

Date: Tuesday,

February 20, 2001 3:12 PM

First I

have a shot of the JCWhitney saddle blanket seat cover I hog ringed on to

Rustpuppy’s tattered ol’ bench seat.

It is nice and the only cheesy part is the stupid vinyl piece in the

middle. What exactly is that

for? (ror98-1.jpg)

The cleanup

work on the interior started with soap and water. (ror98-2.jpg) You can see that it needs it.. (ror98-3.jpg)

After a while

and a lot of scrubbing it started looking much better. The original white paint is still

mostly there.. (ror98-4.jpg)

Then I

crawled into ol’ rustpuppy and attacked the masonite cover for the package

shelf. I started out in a rational

way but after a while I was tearing at the aged and brittle as glass masonite

like an animal. I got a snoot full

of nasty dust from the decayed soundproofing mat under the rapidly fragmenting

cover. ( made me sick for the

evening) Finally the masonite was

all gone and the ugly mat exposed.

(ror98-5.jpg and ror98-6.jpg)

I got out

the heavy duty shop vacuum and removed the mat in tiny fragments. It was falling to bits and could not be

moved any other way. Then I

cleaned up the bulk of the really nasty residue with a mop so I could do it

without climbing inside. After

mopping up 90 percent of the residue I painfully climbed in and finished the

job by hand. It is looking pretty

good back there now.. (ror98-8.jpg)

I only

saved one little fragment of the torn apart masonite package tray cover to show

you.. (Ror98-9.jpg)

Rick

Draganowski

(tearing at

old cars like an animal)

Subject: Return of Rustpuppy report 99

Date: Tuesday,

February 20, 2001 6:59 PM

Now that

the interior is clean it is time to do stuff with steel. I plan on making a sealed steel

firewall between the passenger compartment and the trunk. Partly because that is the rules but

mostly because I want the exhaust fumes which come in through all of the rust

holes in Rustpuppy’s cosmetically challenged body to stop gassing me.

Ror99-1.jpg

is the starting point. About 50

bucks worth of 28 gauge by 20 inches by 30 feet steel valley flashing. Since I am at the end of the

world here I have to make do with what is available. 30

feet of the stuff should last me a long time.. (it is a particularly repellent poop brown in color..)

I start

on the package tray cover by laying out a cardboard master template on the

trunk lid. I am measuring 5 inches

in from where the steel should end inside. You can see the little marks if you look close.

Then after connecting the dots I cut out the

template. (ror99-3.jpg)

For fun

at this point I struggled with the steel to flatten out and cut off a

piece. It was a real Laurel and

Hardy moment as the coiled steel did not cooperate.. Eventually I won because I outweigh it by a lot.. (ror99-4.jpg)

Back to

the template work. I took the

initial cut of the master template and put it back on the trunk for

verification at 2 inches.

Naturally it was a little screwed up. (about ¼” off on one side of the curve) (ror99-5.jpg)

After

trimming off the screwup I went ahead and made a check template from the master

template using come aluminum covered building paper. Easy to cut using a razor knife. (ror99-6.jpg)

Then I

struggled my fat ol’ bod into Rustpuppy with the check template and put it into

proper position..

(ror99-7.jpg)

Too

cool! It fit perfectly. Now if the weather will cooperate

(it has been raining buckets all day and probably will tomorrow too) I can use

the check template as a guide to cutting the brown steel. I can use my air driven sheet

metal nibbler to do the cutting so it should be fun and easy.

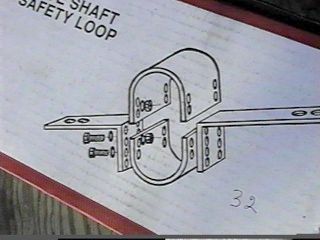

Went to

town in the rain today to pick up some more (3 rattle cans) of the self etching

gray primer. I plan on using it as

the interior motif.. Got some

battery cable stuff and terminals to use on the master cutoff switch too. It and the Lakewood driveshaft safety

loop are on the way from Jeg’s as I speak..

More to

come..

Rick

Draganowski

(rain, rain,

go away..)

Subject: Return of Rustpuppy report 100

Date: Sunday,

February 25, 2001 8:28 PM

After 5

days of 40 degree rain with wind the weather finally cleared up to make a

beautiful sunny day.

I

ordered the driveshaft safety loop from Jeg’s last week and it showed up on

Friday so today I started digging into the installation. First I got Rustpuppy up high enought

to crawl under and mess about.

The plywood is because the ground is still mighty soggy.. (ror100-1.jpg)

I set

the Lakewood loop parts out to take a look at. Something seems wrong with them.. More on this later..

(ror100-2.jpg)

A trial

fitting in the highest setting showed a clear lack of even coming close to

fitting. I have the jack holding

it up temporarily. It is

just too low on the bottom and too low on the top.. Bummer..

(ror100-3.jpg and ror100-4.jpg)

Ror100-5.jpg

shows the parts lined up at the highest setting possible with the Lakewood (

read, Chang Metalworks, Hunan Province, Peoples Republic of China) supplied

holes.

Ror100-6.jpg

shows what might work with some drilling and cutting. The lower loop would be shortened by about 1 inch from this

picture and the L-shaped tails trimmed off..

Ror100-7.jpg

is the Chinese version of the loop.

Notice that they drilled the multiple adjustment holes in the long arm

of the bar instead of the short one..

And there are holes missing from the loops. Somebody did not know what they were making and didn’t

know how to read the blueprint..

Bummer..

Ror100-8.jpg

is the actual design pictured on the Lakewood box. Notice the differences in the location of the holes..

Oh, well

I expected to have to modify it.

Just not this much..

Without changes it looks like it is set up for a 4 wheel drive monster

truck or something..

Hmm..

You don’t think that Jeg’s sent the truck kit by mistake?

I will

look into it tomorrow..

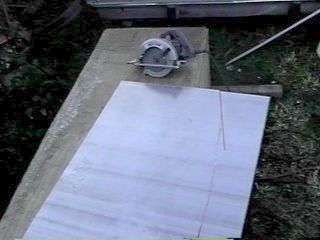

On

another front I wrestled with the stupid coiled up steel and decided that if I

was going to put a firewall in Rustpuppy it should have a structural purpose.

The steel was so bent up from being coiled tight that I couldn’t do nothing

with it. I took the balance of the

steel coil back and picked up a couple of sheets of 0.090 aluminum from one of

the local boatbuilders.

(ror100-9.jpg)

I will

be attaching it all the way around (inner fender wells, floor, and along the

top of the seat back area) to stiffen up the chassis. And the package tray will be structural as well.. I will cut the aluminum

with a carbide blade on the Skilsaw.

What an incredible noise that makes...

More to

come..

Rick

Draganowski

(several

days of good weather coming, That

is good..)

Subject: Return of Rustpuppy report 101

Date: Monday,

February 26, 2001 6:13 PM

Considering

my options on cutting the driveshaft loop to get it right I called town to see

if anyone had a reasonable priced chopsaw in stock.

No one

did but I begged the owner of our Ace hardware store to do the four cuts on his

big Skil chopsaw. I

also put in an order for one of the DeWalt 14” 15 amp jobs for myself. (about 220 bucks.. Rushing out in a buying frenzy

again.. But it is for the

company..)

Anyway

Dan did the cuts and I cleaned up the ends on the grinder and now it is time to

drill the 12 holes needed..

Setup is going to be tricky on the curvy thingie but I have a big drill

press and a lot of clamps and vises..

Tomorrow is another day..

(hmm.. I say fiddlesticks

instead of cussing too.. must have

seen Gone with the Wind when I was too young..)

So

Ror101-1.jpg shows the final configuration of ol’ Loopy.. And after checking Bruce’s

picture against Rustpuppy it looks like the floor where the loop mounts is more

than one inch and mebbe almost 2 inches lower in the Disco.. No wonder nothing seemed to work..

The last

picture for today is a ray of hope.

Spring is definitely starting to show up here. The warmest places are showing the daffodils.. See ror101-2.jpg..

With the

sunshine and blue sky along with the 67 degree temperature today it is really

encouraging.. Most of

my orthopedic problems improve greatly with the better weather and my Nova work

production should greatly improve..

More to

come..

Rick

Draganowski

(will be

slicing steel like bologna next week..)

Subject: Return of Rustpuppy report 102

Date: Wednesday,

March 07, 2001 3:46 PM

The

holes needed drilling in the cut off pieces of the Lakewood loop. The drill press made it much

easier.. (ror102-1.jpg)

The bolted

together loop and the cut off extra bits show up in ror102-2.jpg. Notice the pronounced dihedral in

the wings.. I think that

will be a problem..

It seems

the Chinese metal bending technology cannot quite make a right angle yet. Ror102-3.jpg shows the L-brackets clamped

down. If the bends were right the

ends would line up.. Not...

The

solution was careful cold-forming of the parts to conform to the task at

hand.. Using a BFH.. (ror102-4.jpg) That is my little #5 hammer (only

3 lbs) Number 6 is 8 lbs..

We have

had a very dry winter..

Rainfall is down to only about 30% or less of normal. You can see the grass growing on the

lawnmower is starting to suffer from lack of watering..

After

crawling under, fitting, crawling out, hitting it with the big hammer, and then

crawling under and fitting some more and then doing it again and again I was

tuckered out. The project

stretched into several days because of weather and health problems..

Anyway

had dropped the exhaust pipes because I knew that they would interfere with ol’

Loopy.. I have the long

tailshaft in Rustpuppy and the loop has to be mounted about 3 inches farther

back than ordinarily.. But

surprise, surprise! After getting

it bolted in I find that if I turn the bottom four bolts around so the heads

are on the outside of the loop I have about ¼” or so clearance on both

sides.. Cool. I had expected to have to take

the loop back out till I had the exhaust system properly re-installed for the

changes made..

Ror102-6.jpg

and ror102-7.jpg show the final setup on ol’ Loopy.. (notice the one screwed up hole in the floor, damn, I can

never get anything quite right the first time..) It was a bit of a struggle but I promised Chuck Butcher that

I would put a loop in even if I didn’t have to..

Now I

gotta get the exhaust system hooked back up and get back to work on the

interior..

More to

come..

Rick

Draganowski

Subject: Return of Rustpuppy report 103

Date: Saturday,

March 10, 2001 6:32 PM

Yesterday

I took care of the exhaust hookup on the drivers side and today got the

passengers side squared away.

Ror103-1.jpg and ror103-2.jpg show how close the exhaust pipes are to

ol’ Loopy. It looks like

only 1/8” on the drivers side and over ¼” on the passenger side.

When I get the exhaust pipes modified to fit correctly

without the probe and drogue kludge I will have Tim make sure that there is

plenty of clearance.

I was

amazed at the like new condition of the left front body bushing rubber

biscuit. That is an original one

and it has been there since late 1975..

Long time for a rubber part..

(ror103-3.jpg)

The

exhaust hookup was complicated by the fouled up measurement I made way back

when I first got Goody going in Rustpuppy.

The two

probes I made, I call them Orville and Wilbur, are identical twins. Orville on the drivers side mates with

a drogue I call Mary Elizabeth.

She is thrilled to be getting any probe at all and works just fine.

Wilbur

over on the passengers side wound up with a drogue I call Sheila. (after a girl I dated back in my Space

Center days..) Now Sheila requires

a lot more than Mary Elizabeth to make her happy. You know what I mean.. Things were fitting so badly that the Super Turbo on that

side was hitting on the floorpan and making really terrible sounds..

So I had

to make an extension for Wilbur to make things work. You can see the probe augmentation in the mated pair in the

background in ror103-4.jpg. With

the use of the extension Wilbur and Sheila managed to make things come together

properly and get the job done..

Ror103-5.jpg

shows the Mickey-Mouse emergency brake hook thingie I made after losing the

proper part in the grass during the rear axle replacement. It is much shorter because I just bent

it to fit so I didn’t have to move the adjustment nut back to where it

belonged. I was anxious to get on

the road you see..

It was a

beautiful sunny day today and I think I got another little sunburn because I

started early and the shade from the shade tree was missing.. You can see it was great in

ror103-6.jpg..

I think I burn so easily because living in Oregon for 21

years has given me a very pasty white frog belly looking skin.. When I lived in Florida or Texas

it was completely different.. When

I was laying on the plywood in the sun working on the exhaust system I pulled

up my pantlegs to get some sun on my pasty ol’ legs.. It was creepy seeing them in the sun bare. Like a dead man.. You can see the shade hadn’t got

to protect me yet in ror103-7.jpg.

When I

was making the extension for Wilbur I hauled out the Chopsaw and set it

up.. Cutting steel like

bologna.. Too

cool... I love it... You can see the little end off

the extension sitting on the base of the saw.. (ror103-8.jpg)

More to

come..

Rick

Draganowski

(making

sparks is good)

Subject: Return of Rustpuppy report 104

Date: Tuesday,

March 13, 2001 6:16 PM

Moving

ahead on the interior project I started with the template (made from aluminized building paper) sitting on

the handy box the rear axle came in..

(ror104-1.jpg)

Ror104-2.jpg

shows the target area that will be fully boxed in with the 0.090 aluminum.

When I

attempted to cut the aluminum to the correct shape (making an enormous noise

with the carbide bladed Skilsaw) I found that I could not cut anything but a

straight line. Not very good. (ror104-3.jpg)

After searching

for hours I found my air powered nibbler.

Duck soup with this I thought. Not. The

jaws of the nibbler were jamming and I could make only a tiny nibble. Bummer.. (I think the nibbler is rated at 0.63 aluminum and was

overloaded at 0.090..) (ror104-4.jpg)

But

skill and science prevailed and the job got done.. See ror104-5.jpg..

I put on

the Starrett metal cutting blade for my 12” Craftsman antique wood bandsaw that

I had bought several years ago for cutting aluminum. Then I had to turn the saw around to get the clearance

to slide the long workpiece through there.. The blade speed is still set for wood so it really

zips through the aluminum..

(ror104-6.jpg) You

can see that end of my shop is overloaded.. Note the old Nova 250 six TH200 assembly crowding up the

area.

I

notched the plastic rear window trim bits to make room to slide the aluminum in

and it went in fine and fit perfectly.

Excellent, better than I expected.. (ror104-7.jpg and ror104-8.jpg)

Next it

is time to make the template for the vertical firewall piece. It will extend from the top clear down

to the floor and be fastened all around to structurally reinforce the body of

ol’ Rustpuppy.. Lotsa

crawling around in the back seat area for the ol’ cripple coming up..

More to

come..

Rick

Draganowski

(bandsaws

with narrow blades is good)

Subject: Return of Rustpuppy report 105

Date: Wednesday,

March 21, 2001 6:10 PM

We left

the story with me about to crawl my old fat body into the back seat area and

make a template for the vertical firewall.. Ror105-1 shows the first cut at the job. I use a two stage process with these

kind of projects. First a rough

template which gives me the information I need to generate the operational

template. I have found that

it is impossible to get the initial template fitting good enough because of the

inevitable mistakes that creep in.

Ror105-2.jpg

and ror105-3.jpg shows the rough template being transferred to the operational

template.

The

initial fitting of the operational template shows the fine trimming needed to

make it correct. (better a little

too big than too small) (ror105-4.jpg)

After a

couple hours of cutting and fitting I was happy with the result.

(ror105-5.jpg)

I have

big impressive scars in my hands from working with sheared or freshly machined

metal that has not been deburred and the edges broken. I took the time to do it with my

nifty little deburring tool.

(ror105-6.jpg)

Then

securely clamping the operational template to prevent shifting during transfer I

got the correct outline on the aluminum sheet. (ror105-7.jpg and ror105-8.jpg)

At this

point I sat an looked at the pattern on the sheet and thought..

It would

be difficult and downright dangerous to try to manhandle a piece this big

and cut it out on the

bandsaw. Some experiments with the

Sawzall and scraps were no fun either.. What I needed was a plasma cutter.. Hmmm.. Them cost serious bux..

Then I

realized that Wayne Adams at the Sea People Manufacturing boatworks (where I

bought the aluminum) has a spiffy plasma cutter..

I

bundled the sheet into the Suburban and hit the road to the boatworks..

That was

yesterday afternoon. Wayne

sez today it will be ready to pick up tomorrow.. He would have done it today but he forgot and when I called

to remind him he had left his phone off the hook.. Bummer..

Made the 10 mile trip for nothing.. But wait.

I found some great short angle pieces in Wayne’s scrap box to make the

needed brackets for the sides and bottom of the firewall so it wasn’t for

nothing..

The best

way to make difficult cuts in metal is to have someone else do it..

More to

come..

Rick

Draganowski

(when is

a cheap plasma cutter coming on the market?)

Subject: Return of Rustpuppy report 106

Date: Friday,

March 23, 2001 4:26 PM

The

weather has been crappy for two days now.

50 degree drizzle mixed with cold fog and the slugs have been dancing

all over the yard.

Yesterday

afternoon I fetched the aluminum firewall from the boatworks and with a bit of

a break in the weather got some stuff done today.

Ror106-1.jpg

shows the cutout aluminum next to the pattern. Ol’ Wayne did a pretty nice job on the cutting. He just used his big bandsaw and never

even had to fire up the plasma cutter.. He charged me 10 bucks and it really was worth it..

Naturally

the edges all around were savagely sharp and jagged so I took the angle grinder

with the flap disk and cleaned it up all around on all edges. I can still taste the aluminum from the

dust kicked up.. See

ror106-2.jpg..

Then it

was the big moment. Will it fit in

Rustpuppy?

Ror106-3.jpg

shows the answer..

Cool.. Pretty close and

with a little more grinding it will be perfect..

It is

supposed to rain buckets this weekend so progress will probably be slow..

More to

come..

Rick

Draganowski

(sloshing

around on the “Happy Slug Ranch”..)

Subject: [nova] Return of Rustpuppy

report 107

Date: Monday,

March 26, 2001 4:54 PM

It did bucket

down Saturday and most of Sunday but late Sunday afternoon the break came. I proceeded to mark and grind the

firewall to clean up the last non-fitting bits. It came out nice.. See ror107-1.jpg and ror107-2.jpg..

Then I

got ready for the primer coat. I

am using a dark primer from DupliColor for the package shelf becase the cool

self-etching stuff from NAPA is much too light in color.. When I washed the parts prior to

painting I could see that there was a oily film adhering to the surface. I bet the rolling mill has switched to

silicone oil.. And it don’t

wash off.. Rats.. Sanding it off is the only answer.. Just like the Karate Kid..

Wax

on... wax off.. wax on... wax off..

Ror107-3.jpg

shows the package shelf with the self etching primer (two coats).. Too light.. Later you will see it with the dark gray primer finish coat..

It took

quite a while to do the wax on.. wax off.. trick on the firewall.. I use 6” self adhesive silicon carbide

open grit sanding disks stuck back to back.. No pad, just by hand.. Ror107-4.jpg and ror107-5.jpg.. (need a d-a sander..)

Then the

primer coated pieces went in for the last time.. ror107-6.jpg

Today I

dug into the riveting job.. Just

drilling and riveting and making brackets in a frenzy.. The riveting job took 4

hours and actually was a lot of fun..

The air powered riveter is great..

Ror107-7,jpg

shows the firewall where it ain’t moving from and ror107-8.jpg shows the dark

grey (almost flat black) package shelf..

It ain’t going nowhere either..

Finally

tomorrow I am cleaning up, finishing the primer interior theme and maybe

getting the seat back in.. Then it

is seat time again!..

If it

don’t rain again.. Sigh...

Hoping

the weather stays nice..

I gotta list..

1) replace front shocks with NAPA

whites

2) transplant 1” anti-roll bar from

Junkyard Dawg using the polygraphite bushings and links from Aren.

3)

finish

final adjustment on left front wheel camber

4) install battery cut off switch and

put 3/8” tie down bolts on the battery

box..

5) then it is G-Tech time..

6) and mebbe spend some practice time

up at the 1/8” mile strip up in Coos Bay.. (but it is 70 miles away, sigh..) It

would be best to make a fool of myself there since no one knows me.. It is much easier for me to be an

idiot in front of strangers..

Rick

Draganowski

(rain, rain,

stay away..)

Subject: Return of Rustpuppy report 108

Date: Thursday,

March 29, 2001 1:12 PM

It did

rain a bunch more but yesterday it ended. Just cool fog so I busied myself making some steel

straps to reinforce the aluminum seat relocation brackets. After they went in I finished the self

etching primer interior theme..

See ror108-101.jpg, ror102.jpg, ror103.jpg, and ror104.jpg.. Notice the matching duct tape trim on

the seat belts..

Then the

issue of moving the 85 lb seat assembly from it’s safe haven in the barn/shop

to Rustpuppy. It is too cumbersome

and heavy to try to walk with for an ol’ cripple like me so I hit on the idea

of plopping it on a small silver tarp and dragging it across the soggy muddy

yard..

That

worked good.. (ror108-5.jpg and

ror108-6.jpg)

It was a

real hassle getting the seat back into Rustpuppy so I took my time.. (and wasted most of the

afternoon..) But eventually

it was in place. (ror108-7.jpg,

ror108-8.jpg and ror108-9.jpg)

What a relief that was..

But, (why is there always a but?)

The

addition of the steel straps to the seat brackets changed things just enough so

the bolts didn’t quite line up..

Things never seem to fit perfectly the first time.. I quit for the day, leaving the

boltup work and the seat belt threading and tightening down for today..

I had

hoped to get at least 8 hours of sleep last night but the suppressed excitement

of knowing that Rustpuppy would be on the road the next day defeated me.

So I was

out bright and early digging around ond the misaligned bracket problems.. (the

lack of sleep is going to cost me later if I am not careful)

Loosening

up all the bolts and a bit of judicious prying and hammering and the hardware

all came together. Considerable

standing on your head time in the back seat area but I got through it safely..

It was a

great feeling to sit down in Rustpuppy and start her up and make her move.. I

went for about a 5 mile run to see if everything was ok.. It was.. It is funny how strange (low and perky) Rustpuppy feels

after wheeling the big old Suburban for a couple months..

I parked

her up next to the Suburban and will go to town in her just after finishing

this report.

(ror108-a.jpg)

More to

come..

Rick

Draganowski

Subject: Rustpuppy goes to Town.. No cheese with the whine..

Date: Thursday,

March 29, 2001 4:45 PM

The trip

to town went well. I stopped at

the saw shop to see Chris and show off Rustpuppy a little.. His helper wasn’t at the shop so

Chris couldn’t go for a ride..

Then after the mundane chores

(groceries) I stopped at Jeff’s office. I have been aggravating Jeff since 1980.. He put his kid in charge of the

office and piled his bulky bod into Rustpuppy.. (he weighs over 360lbs.. I am a lightweight at 296..) Between us we were the equivalent of

almost 5 people..

Anyway after we got away from town, and I could show off a little, his

responses were as follows..

Launch-- Holy Shit!!

1-2

shift- Holy Shit!!

2-3

shift- Holy Shit!!

I guess

he was to stimulated to be creative..

With

Jeff in the car the traction in first was much improved.. I could barely spin the tires at

all... Hmmm.. On some tracks it may be

worthwhile having a passenger..

Mebbe a smaller one..

I am a

little concerned about the whining coming from the new axle. It is very noticable at certain rpm’s

like there is a resonance in the system..

I think

the hocky puck like polyurethane front eye bushings on the rear springs

combined with the hard polyurethane spring pad adds to the noise transmission

to the floorpan. And guess what I

have riveted solidly to the floorpan almost right were the spring mount

attaches.. A nice resonant

piece of aluminum.. Hmmm..

I notice

that since I took the carpet and pad out of the Suburban the 10 bolt in there

whines a little at certain speeds too..

I am

stilll going to do some recording of the whine and mebbe get with Wade (the

axle builder) about this issue..

Ol’

Rustpuppy ran flawlessly today..

The only detail is a little roughness in the motor above 5600rpm.. I suspect the bone stock Delco 1977

truck HEI just ain’t cutting it above 5500rpm..

Now that

it is test and tune time I think I will transplant the high voltage coil off

the Proform distributor and see if that makes a difference..

I am not

sure that the front shocks on Rustpuppy even need replacing.. On the bumpy back road to my place the

shocks seemed to be working just right..

Hmmm... That just

leaves the camber fine tune and the neutral interlock switch wiring.. And the trunk battery hold down bolts,

and the main battery disconnect..

And a ton of body work..

And the

whine recording and investigation..

Tomorrow

is another day..

More to

come..

Rick

Draganowski

(you

don’t notice the whine when you are racin’..)

Subject: Rustpuppy Run Test&Tune 1

Date: Thursday,

March 29, 2001 6:17 PM

I

couldn’t hold myself back so I dropped everything in the office and got

Rustpuppy back on the road..

On the

southbound run everything was perfect, the weather fine, the road fast, the

wind still, everything but...

Nother

damn but.. Rustpuppy was not

quite up to race operating temperature from the easy 2 mile downhill trip to

the head of Rustpuppy Run..

So there

was a hesitation at launch. Not a

bog.. Just a drawn out

hesitation... Damn.. After that

Rustpuppy took off like a scalded cat..

But the results of the Southbound run was a little disappointing.

Remember

though, no tuning has been done yet..

That is a starting point..

I went

up to the private turnaround.. Ever

since I got caught up in the herd of rollers I have been shy about turning

around at the rest stop.. I

was calm and clearheaded and felt confident.. But the best laid plans.. I was a little hurried to stage since there was

following traffic and I had very little time.. The launch was perfect though with the front and

rear of Rustpuppy eagerly leaping into the air as both rear tires spun about 1

½ revolutions..

But

there is another damn but...

There was some uneveness in the pavement since I was staging about 100

feet up from the best spot and the traction was messed up. With the posi axle when one tire

lost traction the rear jogged to the right with alarming speed.. Since I was on the causeway and there

was no room for this kind of foolishness I let up on the throttle

instinctively.. And naturally the

damn TH350 upshifted because I had signaled with partial throttle.. Poop..

I stayed

on it but the run was a dismal 14.26@102.3..

And the

wind was picking up and the dew

forming so it was time to go home..

More to

come..

Rick

Draganowski

(Test&Tune

is good)

![[ Back Button ]](../gif/t_back.gif)

![[ Go Home Button ]](../gif/t_home.gif)

![[ Next Button ]](../gif/t_next.gif)