Subject: Supernatural influences??

Date: Wednesday,

November 15, 2000 8:25 PM

The rain

stopped for a few hours today so I got to spend an hour farting around with

Rustpuppy.

I was

lining up my ducks for the axle removal. (getting all the needed tools and equipment together)

I need

the 7/16 tubing wrench for the brake hose fitting. I could not find the 7/16-3/8 tubing wrench

anywhere.. I have had the set of

tubing wrenches for 15 years and they have always been there before.. (I try to put my tools away after using

them)

Then I

remembered that I had just (about 2 months ago) bought a high zoot set of

crowfoot tubing wrenches.. (well

mebbe medium zoot as they are the 25 buck NAPA Taiwan jobs)

I got

them out and found that the 7/16 one (clearly marked) was actually a 13mm

one.. Bigger than the ½”

job.. What is going

on??

And when

I was putting the Lakewood bars on my 11/16” deep sixpoint socket turned up

missing.. ( I have had that set of

sockets without losing one since 1967..)

What is

going on?

Is

someone trying to tell me something?

Rick

Draganowski

(bad weather

and bad luck.. bummed out in

Oregon)

Subject: Tubing wrenches and wet

traction

Date: Friday,

November 17, 2000 8:13 PM

I took

the screwed up set of Taiwanese crowfoot tubing wrenches with the 13mm version

of 7/16” back to NAPA yesterday and gave Tracy a hard time about it. Having to order in the replacement set..

Anyway I

bought one of the high zoot NAPA jobs to replace my missing tubing wrench. It will probably turn up now to restore

balance to the universe. This one

little American made wrench cost $11.70..

Them cheap Chinese and Taiwanese tools are distorting my sense of value.

Now I am

set for the axle removal on Rustpuppy.

On

another subject entirely I took the Suburban to town last Tuesday in the middle

of the heavy rains.. I

decided to put the stock 235/70-15 size BFGoodwrench Radial T/A Long Trail’s

because I wanted better wet traction than the much wider tread General tires I

had before..

It

really paid off. The BFG Long

Trails have about twice the wet traction.

I did a few test emergency stops to get the feel of them and they are

really good wet weather tires.

Worth

twice what I paid because of this one feature..

Rick

Draganowski

(more sun

tomorrow, I hope..)

Subject: Return of Rustpuppy report 83

Date: Monday,

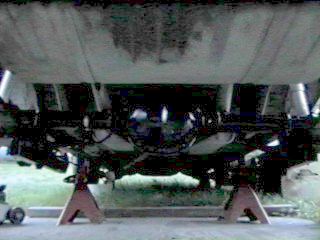

November 20, 2000 8:24 PM

I still

haven’t heard back from my mechanic in North Dakota about the pricing on the

8.5” axle but I have been plugging away a little at a time on getting the 7.5”

job out. In a desperate move to

get more room for my fat ol’ bod under Rustpuppy I put the front subframe up on

blocks. Since I was using three

stacked short 4x4’s for each block I lined one up to the long axis of Rustpuppy

and put the other one at right angles to the long axis. This prevents the possibility of

tipping the narrow blocks over when the heavy tugging starts. Then I jacked up the rear a bit more

and put 1 ½” blocks under the jackstands.

Plenty

of room for crawling around under there now.

Today we

had a break in the weather with reasonable temperature and dry enough (won’t be

really dry till next June or so) for some work. It extended past dark so I was out rolling around under

Rustpuppy with the droplight.

First I

set up a siphon to start draining the gas tank to get ready for dropping it

later. (I got most of it out) Then

I got to try out my new high zoot American made tubing wrench to get the brake

hose disconnected. Wow! it took about 40 lb ft of torque to

break loose the tiny 7/16” fitting.

Never would have gotten it off with vicegrips. The tubing wrench worked great though.

Then I

addressed the emergency brake cables.

It is cool having a car this old and this rusty on top with fully functional

factory emergency brakes. The

adjustment nut had to be backed off quite a ways so it was a pretty long

session under there with wd40 and oil fighting for each ¼ turn. But persistence paid off and I finally

was able to release the couplings on the cables and slide off the neat spring

clips which hold the flex cables to the frame bracket.

Then I

went through the drill of getting the driveshaft uncoupled from the axle. Shift to neutral, crawl under, rotate

driveshaft to make two bolts accessible, crawl out from under, shift to park,

crawl back under, remove two retainer bolts, crawl out from under, shift to

neutral, crawl back under, rotate driveshaft 180 degrees, crawl out from under,

shift to park, crawl back under, remove the other two bolts and push the

driveshaft forward enough to allow it to drop down. Whew!

I put a

ziplock baggie and some big rubberbands on the exposed u-joint to protect it

and prevent the cups from falling off.

While I

was under fooling with the stuff mentioned above I was thinking of the exact

technique I would use to actually remove the axle. I hit on this idea.

The six

smaller bolts holding the front spring retainer plates to the rear subframe are

in perfect condition so I am going

to remove them to drop the front of the springs/axle/traction bars

assembly. I replaced the bottom

rubber bushings on the rear shackles just 4 or 5 years ago so I know them two

bolts are in perfect condition. (didn’t do the top ones since the tank has to

come out for them, bummer) So just removing them frees up the whole kit and

kaboodle to be dragged out from under as an assembly.

More to

come..

Expecting

cold front and rain later tonight so it may be a while..

Rick

Draganowski

(slow and

steady)

Subject: Return of Rustpuppy report 83

addendum 1

Date: Tuesday,

November 21, 2000 6:17 PM

I

snapped these pictures today to go with report 83. And Chuck, to check the integrity of the jackstands and

blocking, I body slammed Rustpuppy both sides front and back (about a 200lb

hit) with no effect.

I spent a

minute underneath planning my next move.

I am a little discouraged about the way the filler on the gas tank

sticks out over part of the subframe to cause the tank to have to be pulled

forward and then down. I am

worried that it cannot be done without spilling gasoline on everything

including me. That would be a

disaster as I cannot afford to get that contaminated because of my Deloris’s

chemical sensitivity.

So I am

leaving the tank where it is and just working around it..

Probably

just spend a couple of minutes this evening and get the bottom of the shocks

free..

The

promised cold front and rain for today went south into California, (yay!) So the weather is still reasonable..

More to

come..

Rick

Draganowski

(crawling

around under rusty old cars and having fun)

Subject: Return of Rustpuppy report 84

Date: Thursday,

November 23, 2000 6:04 PM

As I

mentioned in several letters about my quest for an 8.5” rear axle for Rustpuppy

I have decided on an expensive (850 bucks plus) solution. My only justification is that the axle

is not really for the Rustpuppy but for the future. The 8.5” axle that came stock in Junkyard Dawg is gone with

the miserable Ford 8” lurking there so the Dawg will need a proper axle when

the time comes. And since I am

planning on a pretty stout 406 motor for the Dawg it better be a reliable one.

When it

comes time for the Dawg to get the high zoot axle from Rustpuppy, the stock

2.73 7.5” axle from Yakima Sue will replace it.

So the

nice 10bolt 8.5” axle with the Torq-Line Posi and 3.73 Richmond gears is an

investment in the future and an affirmation of life.. (pretty windy sentence, heh..)

And

dropping that much dough out of the Nova Fund will discourage me from any more

Nova purchases for a while.. (have

a tendency to rush out in a buying frenzy.. and 3 Novas should be enough for

now..)

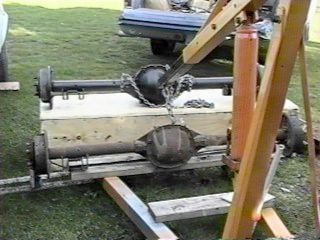

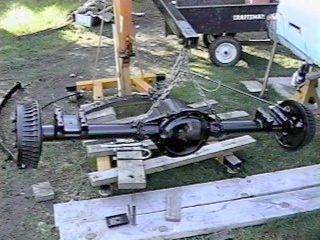

Back to

the business at hand. Yesterday I

removed the 4 nuts holding the rear spring shackles together. Slow but fun work. Today I got a short window and

started by prying the shackles apart and dropping the rear of the springs. Then a few moments on the 6 spring

retainer bracket bolts and the axle was free. A few minutes of prying and tugging skidded it out

from under Rustpuppy. (ror84-1.jpg)

Ror

84-2.jpg shows my little assistant Albert. He was with me all the time I was working today. You know the giant slug is the official

State Animal of Oregon..

Have often dreamed of starting a football franchise here.. The “Oregon Slugs.” Catchy name, don’t you think? Albert is just a baby and if he is

still around when he grows up I may get a saddle for him and try to tame him

enough to use for hunting. Giant

slugs are a lot quieter than horses..

In the

closeup of the axle you can see where the pinion snubber was hitting before I

put the Lakewood bars on..

It will be interesting to see what exactly went wrong inside.. Sigh.. another autopsy.. I still haven’t got around to opening

up Knocker..

This

picture is for Alex.. See

the perfect 24 year old bolts which were holding the front spring brackets to

the subframe.. I

recall that Scott Windle had a bit of trouble with these. I wonder why GM used the cheap clipon

nutplates on these high-corrosion area critters?

By the

time I took ror84-5.jpg the fog was creeping in and the light was going for the

day..

A small

step but an important one. Having

things out where you can get to them is good..

More to

come..

Rick

Draganowski

Subject: Return of Rustpuppy report 85

Date: Tuesday,

November 28, 2000 9:31 PM

Not a

lot of wrenching but a bunch of administrative work. I got a quote back from Richie Mulligan (the guy who

advertises in NNN.. see below..

“RICK...a

totally rebuilt unit from my stock with new 3:73’s, clutch pacs, bearings and

seals, drum to drum, less brakes+crated and ready to be trucked is $1070.- It’s

best to call me for payment & time frame arrangements, credit cards

accepted, my number is 973-786-6668.”

Anyway

that was lots more than I expected from some of the stories I been

hearing. I got another quote for

1200 bucks plus core and 300 for axles so you see the 850 bucks for a new

Torq-Line and the Richmond gears is not out of line.

But it

got better, I heard from my mechanic yesterday that he has located an axle with

the stock GM posi in good shape and the adjusted price is 700 bucks.. That includes new Richmond 3.73

gears, rebuilding the posi, all new bearings, and new seals... The backing plates are included

so I do not have to recycle the 7.5” jobs.. Pretty cool..

And he sez that the shipping will be about 160 bucks.. I dropped a 250 buck deposit on it in

the mail with a note urging him to hurry as Christmas is coming soon..

I

managed to find time to skid the little axle completely out from under

Rustpuppy and remove the spring mounts and shackles. I will only scavenge a minimum of bits off of this axle as I

find old junk valuable.. Alex’s idea

of using it as a dummy axle under the Junkyard Dawg and selling the Ford 8”

axle has some merit..

Scott

Windle warned me that the axles have a different dimension from the axle

centerline to the U-Joint so the driveshaft has to be shortened to allow the

bigger one to fit. He said about 1

inch.. I am a little bummed out

about the lack of interchangeability

(they could have used a short U-joint saddle on the big axle and a long

one on the little guy..

Because

of the kindness of good ol’ Ben Meissner I have a nice set of used 8.5” 3.08

gears and the 7.5” axle is just laying around so I made some crude

measurements. From the axle

centerline to the end of the pinion shaft on the 7.5” axle is about 10 ½” to 10

5/8”.. (I said crude) And on the 8.5” gearset from the center

of the ring gear to the end of the pinion shaft (when the gears are meshed

approximately correctly) is almost exactly 11 ¼”...

Hmmm.. There is a definite difference.. My crude measurements come up with

about 5/8” to ¾” and that does not predict where the U-Joint will actually be.. I bet it is close to the one inch

that Scott warned me about.. (he

knows everything.. I am not

worthy..)

On

another front, Yesterday I “Rushed right out in a buying frenzy!” and called

Espo (Springs-N-Things) about an E-Mail quote that Laura sent last week. Before I could stop myself I ordered

new rear springs. (90 bucks plus 10 bucks to push out rubber front bushings

plus 25 bucks shipping or so for a total of 125 bucks for the springs)

And I

then I got even more crazy and ordered polyurethane front spring bushings,

shackle bushings, and those rubber pad thingies which sandwich the

spring.. Plus I needed the 3”

U-bolts for the big axle.. The grand total came to about 246 bucks.. Oh well, Christmas is coming and I have

to put the good axle on somehow..

The spindly

little axle uses 2 5/8” axle tubes versus the beefy 3” jobs on the good axle..

I have

been starting Goody up and running her up to operating temperature every

day. Sort of a pathetic imitation

seat time.. I am hoping to

run out all the remaining gasoline from the tank so I can safely drop it for a

serious cleaning, painting and sock replacement.. I just love the sound of that eager little motor..

More to

come..

Rick

Draganowski

(waiting for

Christmas..)

Subject: Thoughts about shiftpoints

Date: Saturday,

December 02, 2000 11:25 PM

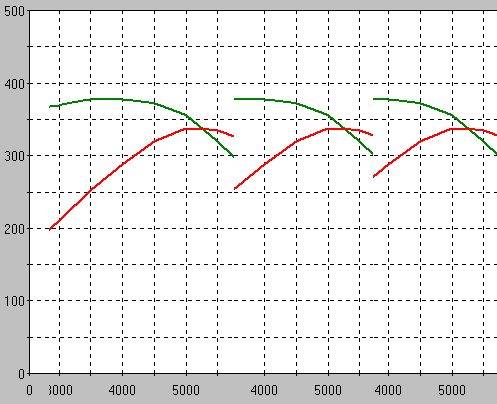

While

waiting patiently for the new axle to arrive for Rustpuppy I did some

calculating and plotting on shiftpoints using the 3.73 ratio..

With the

14” wheels and the 245/60 tires the speeds at the redline of 5700rpm (self

imposed based on just feelings so far) come out as below..

First

gear------- 0 to about 43mph (2800-5700)

Second gear

-- 43mph to 71mph (3430-5700)

Third gear

------ 71mph to 109mph(3730-5700)

This

seems to make a nice complement to Goody’s torque and horsepower curves..

I pasted

together this chart showing an approximation of the combination of all three

gears..

Goody

comes off the line at about 28-2900rpm due to the stall speed of the

Break-A-Way.. After that it

looks like she would be pulling hard..

I can hardly

wait for the reality..

Rick

Draganowski

(waitin for

Christmas)

Subject: Return of Rustpuppy report 86

Date: Sunday,

December 03, 2000 8:58 PM

I pulled

off the too-short flex brake hose on the old axle and took it to town last

Friday. Tracy at NAPA researched

his books and found a replacement part which is 4 inches longer. That should take some of the stress off

of it.. (the NAPA white shocks

seem to be about an inch longer stroke that the stock ones so the hose catches

hell) While I was there the guilt

of thinking about recycling the old wheel cylinders and brake shoes out of the

little axle into the high zoot one overcame me. So I plunked down 56 bucks for new wheel cylinders and

premium brake shoes.. There

is never an end to places to spend money on these wonderful old cars.. (I mean vintage, excuse me)

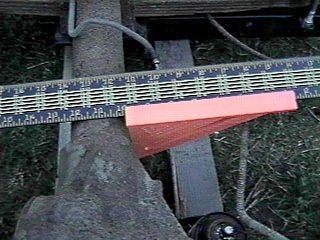

Ror86-4.jpg

shows the condition of the old hardlines on the rear axle..

Still

lookin nice and I probably will have to use them on the new axle..

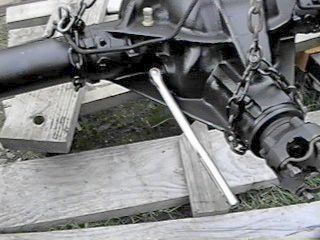

Ror86-1.jpg,

ror86-2.jpg, and ror86-3.jpg show the measurement rig I flanged up to get the

dimension from the front parting line of the U-Joint yoke to the front of the

axle tube. The dimension seems to

be almost exactly 9 7/8”.

The tubes on the 7.5” axle are 2 5/8” diameter. This works out to 11 3/16” to the

centerline of the axles.

Now if I

only had access to a 8.5” axle I could compute the exact difference in

dimension so I could verify the 1” number from Scott Windle. I want to get the driveshaft cut

and ready to go in when the axle arrives.. Scott was not 100% sure of the one inch number and

cautioned me to measure to make sure before cutting the driveshaft. I cannot just swap in a stock Nova

driveshaft made for the big axle as I am using the long tailshaft tranny out of

my old truck in Rustpuppy..

Can anyone help? Just

the measurement from the front of the axle tube to the yoke parting line..

More to

come..

Rick

Draganowski

(little by

little.. progress is made..)

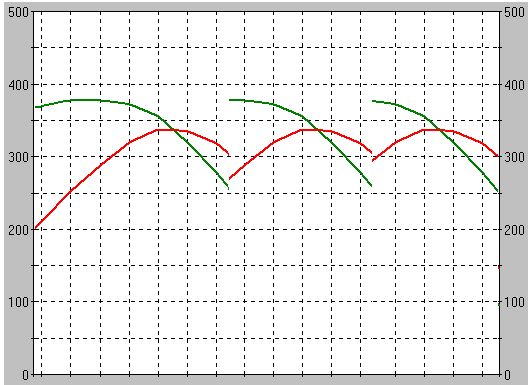

Subject: Second thoughts about

shiftpoints

Date: Sunday,

December 03, 2000 8:16 PM

Chuck

Butcher responded to my first message on this subject with some good

information and a suggestion to use 6200rpm instead of 5700rpm for the shifts.

I worked

up the graph and it looks like he is exactly right..

The

numbers for 6200rpm are:

First gear

------ 0-47mph 2800-6200rpm

Second gear

-47-78mph 3750-6200rpm

Third

gear-----78-118mph 4100-6200rpm

Notice

the horsepower curve is close to being connected.. Cool..

Rick

Draganowski

(having fun

with numbers)

From: “Rick

Draganowski” <dragan@harborside.com>

To: “[NovaList]”

<nova@seas.smu.edu>

Cc: “[Steve

Moore]” <doc3544@aol.com>; “ben

meissner” <bm57@email.byu.edu>

Subject: Return of Rustpuppy report 87

Date: Monday,

January 22, 2001 5:58 PM

Hoping

that getting back into “Return of Rustpuppy” reports will be good therapy.

Going

back to when the Rustpuppy was still on the road (before axle disaster) It was

very cool having the local rodders showing up in a little crowd each time I

stopped for gas. Rustpuppy may not

look like much but has earned a little respect from the locals. The kids seem really nice and

enthusiastic and it is good to be a big frog in a small puddle.

Knowing

that I will need one in the future I had my mechanic Wade in North Dakota build

up a race TH350 for Rustpuppy for the day (inevitable) when the ol’ truck

tranny in her now goes to it’s reward.

Wade sez it is equivalent to the B&M and TCI TH350’s but he only

charges 300 bucks.. The shipping

to me was another 85 bucks but well worth it. The “good” tranny is sitting in my shop, just waiting

it’s turn.

I leaned

on Wade to come up with an axle for the Rustpuppy to get back on the road. He (after several delays from suppliers

and other reasons) built one up with a 2 series rebuilt GM posi and new 3.73

Richmond gears with a spacer..

700 bucks for the axle but the shipping is a killer.. 266 bucks delivered. 136 to the terminal at Roseburg

and 130 to get it to “The end of the World at Gold Beach”..

So it

used up almost 1 large from the Nova fund. (been saving up for 4 years on the fund..)

Then those

most excellent plaques showed up.

I got one aluminum for Rustpuppy and 1 bronze for the shop.. What fun it was to open the

package from the foundry..

Ray, out

of an excess of competitive spirit decided to get an Autometer shift

light.. Naturally I had to

get one too.. Then I

aggravated Ray lots to get the poop together for an adjustable pill. Then, as you know, my

circumstances changed. Now it is

essential that I devote full technical time to getting my company out of

mothballs and back into production.

I realized that I could not afford myself anymore so I aggravated Jeg’s

for a proper pill kit. I actually read the Autometer directions and got the

part number there. The rpm’s are 5600,5800,6000,6200,6400.. That will cover everything I will

ever need.. Now I find

that the 5600 kit is listed in the new catalog. They must have had more complaints than just mine..

I

installed the shift light (just some wirenuts onto the Sun Super Tach II wires)

and a couple hoseclamps. It works

neato, as advertised. It is cool

that the tach and the shiftlight agree exactly..

I had my

mechanic Wade measure the U-joint flange to front of axle tube dimension on the

8.5” axle and report back to me.

It seems the driveshaft has to be shortened 1.3” for it to work with the

new axle. I whined about the

driveshaft problems to my NAPA folks and they tipped me off to a automotive

machine shop down in Brookings (about 40 miles away).

I took

the driveshaft down and left it with Chuck ( a cool guy who builds motors for

the local circle track crowd ) and he had it done in a couple days. I had him straighten and balance it

too. The U-joints on the

driveshaft only had about 8k miles so I expected them to be perfect. Chuck inspected them anyway and found

the front joint was rough..

He sez if there is not enough angle in the driveshaft to work the joints

that they brinell and turn nasty from operating in the same place too

much. With the sagging rear

springs (to be replaced with new stock height jobs I got in from ESPO) the

driveshaft angle was non-existent messing up the front u-joint. The rear joint was ok because of the

pinion down-angle working it..

I never knew this detail..

I went

ahead with the JCWhitney seat cover (saddle blanket style) installation. Ol’ Ray sez that you gotta pull the

seat to maintain your sanity during installation. But I got the seat in a modified location (cause of my long

legs) and it has to be moved all the way forward to get to some of the

bolts. Anyway the shifter is now

in the way and taking it out is no easy task since it was put in before the

motor-transmission assy and the nuts are not falling to hand any more..

So today

I decided to hog ring the daylights out of it where I can reach and just hope

for the best. Crude but effective

like all my stuff..

On

another front I ordered the Earls Solo-Bleeds for the new rear wheel cylinders

(and a set for the front calipers for the future) They came today.

The last

pent up episode in the story is about the expensive ride my new axle is

getting. It left Velva ND

(no wise cracks, it is like the cheese, not the other) and turned north to Minot.. Then it took a 900 mile

detour to Minneapolis.. It

hopped a train in Minnesota and headed for Seattle.. Today I found out it is in Portland OR..

So I

expect it later this week mebbe..

I am

tired of typing..

More to

come..

Rick

Draganowski

(moping but

still going)

Subject: Return of Rustpuppy report 88

Date: Friday,

January 26, 2001 6:25 PM

Yesterday

about noon the far wandering axle showed up at the NAPA in Gold Beach. (It started in Velva ND and went to

Minot ND, Minneapolis MN, Seattle WA, Portland OR, Roseburg OR, and finally

here to Gold Beach OR)

My stalwart

friend Tracy (cool NAPA counter guy) is self-consiously posed next to the neat

crate that Wade made for it.

(ror88-1.jpg)

The box

weighs 185 lbs so Tracy popped it into the Suburban in a jiffy. Then posed again (in the rain) for the

final pic of the day..

(ror88-2.jpg and ror88-3.jpg)

Today

dawned bright and sunny so I had a chance to mess about with the new axle. Ror88-5.jpg shows the box in the sun in

the Suburban. Ror88-6.jpg

shows the poor overstressed and washed up 7.5” axle waiting for the scrap heap.

I

carefully slid the box out and removed the cover. Looking good! (hope it is worth the one large) Then taking

my time I maneuvered it over to the staging area. (ror88-7.jpg, ror88-8.jpg, and ror88.9.jpg)

Notice

the traction bars and springs have been stripped off of the old axle and the

new job is sitting up where I can get started on rebuilding the brakes. (ror88-10.jpg, ror88-11.jpg, and

ror88-12.jpg) Rustpuppy can be

seen waiting patiently to get back on the road in ror88-11.jpg..

I found

the original Haynes Nova manual I bought back on April of 1993. (still had the NAPA receipt inside)

That is when I first got Rustpuppy and before all the rust showed up.. It has been longer than I thought..

More to

come..

Rick

Draganowski

(making

progress..)

Subject: Return of Rustpuppy report 89

Date: Sunday,

January 28, 2001 7:49 PM

The day

dawned yesterday bright and sunny so I started digging into the brakes on the

new axle as soon as I finished my third cup of coffee..

I have

forgotten just how much I hated doing brakes but it all came back to me this

weekend. And in the last 8 years

since I put new linings on Rustpuppy (last brake work I done) I seem to have

forgotten everything I once knew about making the job easier.

I

started by stripping down the nasty passenger side brake that Wade put on the

axle for free.. It was worth about

that much. (ror89-1.jpg) The bits

were kind of eaten up by road salt so I decided to clean up the nasty looking

but much nicer salt-free bits from Rustpuppy’s old axle.

The passenger side wheel cylinder spit up some really

nasty stuff on the old axle. It

was past due for replacement..

Real “Exorcist” looking stuff..

(see ror89-2.jpg)

I

cleaned and wire brushed the bits from the old axle and the backing plate of

the new getting ready for the amazing puzzle which is the reassembly process by

an ol’ idiot.

Note

that the NAPA folks gave me the wheel cylinder for a late 76 Nova and I needed

one for the earlier version.

(ror89-3.jpg)

It was a

good thing that it was Saturday as I jumped into the Suburban and raced to town

to get the right wheel cylinders.

While I was there I picked up the axle lube and brake fluid as

well.. (why is it

always this way?)

Amazingly

enough I managed to get it together (I hope correctly) and only hurt myself a

little bit..

(ror89-4.jpg)

Today

(Sunday) it started sunny but the clouds were rolling in by the time I dragged

my aching butt out to get the other side done. I started on stripping down the drivers side of

the old axle to salvage the ugly but almost rust free bits I would need. (ror89-5.jpg)

I

cleaned up the brake drum, did the initial adjustment and buttoned up the

passengers side of the splendid new 8.5” racing axle.. (ror89-6.jpg)

Ror89-7.jpg

and ror89-8.jpg show the drivers side brakes stripped down and the salvaged

bits from the old axle (I call her “Whiner”)

It was

the work of just a few minutes to clear away the brakes on the new axle

driver’s side. I think I am

getting the hang of this crappy job. (I would hate to do this for a living, as I am too

slow to make minimum wage at it..)

(ror89-9.jpg)

After

much cleaning up and wire brushing I got the bits and the backing plate looking

presentable. (it takes about 1.5

hours for each cleanup.. Too

slooww..) (ror89-10.jpg..

And

finally just at dusk I got the driver’s side together. A cleanup on the drum and found that

the end of the axle was banged up enough to keep it from going on

properly. Several minutes with a

strip of 240 grit wetordry paper cleaned the burrs enough to let the drum on. An adjustment of the brakes (about a

turn out from hanging) and the second drum was buttoned up and painted pretty..

(too dark for pics)

I

expected rain tonight so hand tightened the brake lines into the cylinders to

prevent water from creeping into them and covered the other ends of the brake

lines with plastic bags. The

formed lines for the 7.5” axle are not correct but look like they will work

with some minor forming.. (old

tech word for bending them)

Hope the

rain goes away quick as I am getting anxious to get ol’ Rustpuppy on the road..

More to

come..

Rick

Draganowski

(nice productive

weekend, but not as much as I wanted..

Sigh.. I am too old, fat,

and crippled..)

Subject: Return of Rustpuppy report 90

Date: Monday,

January 29, 2001 9:23 PM

Good

weather but my old bones were creaking today. Small victories and some troubling finds.

First I

was unhappy with the NAPA emergency brake cables. There was a big gap at the flangie thing which mated up with

the backing plate. I scrounged up

a couple ½” ID O-Rings and carefully slid and stretched them over things to get

them into place. Looks like a good

seal.. (ror90-1.jpg and

ror90-2.jpg)

The old

axle (Whiner) is getting ready for a ride on the hand truck. It will languish in front of the shop

till I get around to the failure analysis.. (much later..)

(ror90-3.jpg)

Then

something ugly showed up. I

cleaned up the U-joint saddles and bolts from the old axle and wire brushed the

paint off of the yoke on the new axle.

Turns out there is a right nasty gnarf in the yoke which prevented the

bolt from even starting into the threads.

I was quite disappointed in the quality control by Wade that let this

slip by. I cleaned up the mess as

best I could and at least the bolt works and it looks like it can be usable. But I worry about how much strength was

lost by the damage.. Goody

will be putting considerable torque through there.. Damn, it is always something.. (ror90-4.jpg and ror90-5.jpg show the

damage as found and ror90-6.jpg shows the cleanup)

Moving

right along I got out the new rear springs from ESPO and the polyurethane stuff

and 3” u-bolts.. 200 plus bucks

worth of stuff..

I

struggled with mounting the spring and traction bar on the passengers side

first. It was a difficult job and

much time was wasted. I had to

grind down the spring pads before I could get them to fit up into the spring

perches. Then when I finally got

the u-bolt nuts into place I started feeling like something was wrong.

Something

was wrong. The depth of the recess

in the spring perches on the new axle was only 1 ¾” while the old axle had a

depth of 2 1/8”.. What the

hell?? What is going on? It looks like the traction bar plate is

at least 3/8” from contact with the spring perch flanges.. I do not understand. I had though that the single leaf

spring perch was very shallow. The

perches on my expensive new axle are at some intermediate size??

Was

there an intermediate spring with fewer leaves?

WTF???

The new

springs I got from ESPO have 5 active leaves and a short spacer. (so do the old springs off Rustpuppy) I

guess I can take the short spacer out but that still leaves me at least 1/8”

from being right.. I picked

up extra nuts and internal star washers in town to double nut with lock washer

the u-bolts since they cannot be torqued down in a metal to metal

situation. I hope that will work

well enough..

It has

been a frustrating and difficult day and I am getting a little pissed

off.. And creaking like an

old gate too.. My old

arthritis is really getting to me after the last few days of frantic activity..

See

ror90-8.jpg..

Bah,

humbug!

I have learned

that when the axle is out of the car you_must_turn it completely over to put

the springs and traction bars on with any kind of ease.. I struggled with it the other way and

wasted half a day today..

Bah!

Rick

Draganowski

(Creeaakk,

snap, crackle, groan..)

Subject: Return of Rustpuppy report 90

Haiku

Date: Monday,

January 29, 2001 9:56 PM

removed

hasty paint

ugly sight

presents itself

yoke,

battered, Oh shit

mounting

heavy spring

something is

not even close

spring

mounts do not match

creaking and

groaning

ancient man

with ancient bones

gets bad

attitude

Rick

Draganowski

Subject: Return of Rustpuppy report 91

Date: Tuesday,

January 30, 2001 6:44 PM

Another

fine day for working. Rain had been

predicted for the last three days but they got it wrong as usual.. Nothing but beautiful sunshine..

I

stripped off the passengers side spring and traction bar I put on in a

half-fast way yesterday and spent the first half hour getting the axle turned

completely upside down. Now

that I could see the bottom it was apparent that the paint was sketchy at best

and rust was forming all over..

(half-fast paint job by the builder) I cleaned it up and gave it a nice coat of self-etching

primer.. (love that stuff) You can see the paleness in

ror91-1.jpg..

Then a

nice coat of cheap black enamel and things are ready for serious assembly.

(ror91-2.jpg)

This is

the passengers side spring perch with the tough urethane pad in place. I had to grind almost 0.100 off of the

edges to get it into the perch..

(ror91-3.jpg)

The

spring followed and you can see that it is sticking up about 1/8” or so.. (the pad will compress if I torque the

u-bolts enough..) (ror91-4.jpg)

Then it was fun to finish putting the u-bolts and traction bar on the

inverted axle. (it was a bitch

doing it the other way..

really....) (ror91.5;jpg)

The

other pad and spring was next..

Looking good..

(ror91-6.jpg) The

next pic is a close-up showing about 0.080 or so gap left but the nuts have

only about 30 lb ft of torque.. I

expect if I put 70 or 80 lb ft on them the gap will almost disappear.. See ror91-7. for the gappy stuff..

Ror91-8.jpg

shows the results of a fun day..

The springs and traction bars are on and I will do the final torqueing

of the u-bolts after the axle is installed. I bet the springs will not line up with the front spring

mounts so they will have to be fooled with.. I plan on double-nutting with a lock washer the axle u-bolts

since I may not get metal to metal contact and the urethane will slowly flow to

loosen things up..

The

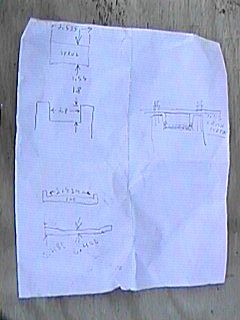

final picture ror91-9 shows my notes and measurements which convinced me that

things would be just fine..

If the

weather holds for just a few more days ol’ Rustpuppy will be on the road!

Rick

Draganowski

(sunshine is

good)

Subject: Return of Rustpuppy report 92

Date: Thursday,

February 01, 2001 7:30 PM

After

getting the neat new ESPO springs on it was time to flip the axle over.. (easier said than done since the assy

weighs over 300 lbs.. ouch!) But I

got after it first thing.

(ror92-1.jpg, ror92-2.jpg, and ror92-3.jpg)

I

thought that now is the best time to check out the damaged u-joint yoke so I

went ahead and installed the driveshaft temporarily. Everything looked peachy-keen.. (ror92-4.jpg, ror92-5.jpg,

ror92-6.jpg and ror92-7.jpg) It is best to find out bad news before putting the

axle under the car..

I expect

rain almost every night so I was sure to put corks in the wheel cylinders to

keep out the water..

It was a

short day as I am a bit physically challenged today..

More to

come, sooner than you think..

Rick

Draganowski

(inspecting

stuff is good)

Subject: Return of Rustpuppy report 93

Date: Thursday,

February 01, 2001 8:31 PM

Another

day without rain (except it is raining like mad as I type this at 7:30pm) so I

got a lot of little things done on the axle replacement project.. I had cleaned up and painted the brake

lines and figured how I was going to mount them. Then I addressed the Earl’s Solo-Bleeds.. Cool invention and they were easy to

install.. (ror93-1.jpg) I also got the ¼” jobs, that I thought I was going to

need, today. Poop! It looks like Jeg’s has discontinued

the Earl’s Solo-Bleeds and is shipping the Russell SpeedBleeders instead.. Oh, well.. I got the four Earl’s I need for old Rustpuppy.

I got

busy on installing the front spring mount brackets and getting the shackles

ready. The, hard as a hockey puck,

urethane shackle bushings all had a pretty rough hole drilled in them. It looks like the cutter they were

using was too dull but they kept going anyway. Anyway all 8 of them had to be drilled out to the proper

size with a sharp 9/16” drill bit..

(ror93-2.jpg) After

drilling and with a little oil they worked slick.. (ror93-3.jpg)

(more crappy quality control, it wasn’t like this before the stupid ISO

9000 crap.. all the paperwork in

the world don’t make up for a lack of pride in your work)

Ror93-4.jpg

shows the spiffy spring bracket.

The other one looks the same except it is left handed..

This

next picture is specially for Alex Bilan and Scott Windle. It shows the drivers side front spring

bracket mounting area. Rustpuppy

may be really ugly and rusty topside where everyone can see but she is

rust-free and beautiful underneath, where it really counts. You can see why I love this fugly

ol’ car.. (ror93-5.jpg.. see the original paint under

there!)

I got

the replacement bumpers for the Lakewood traction bars. It really ticks me off having to strip

the excess rubber off the studs..

What ever happened to quality control and pride in manufacturing? Everything is done on the cheap

anymore.. (ror93-6.jpg)

You can

see why I needed new ones. I had

to really shorten the original ones cause the rear springs were saggin so

much. They were still gapless

too.. I hope the new springs make

a difference.. (ror93-7.jpg)

Before I

forget and fry my new axle I went ahead and filled it with the proper

lube.. (not going to use any posi

additive.. You will hear Rustpuppy

creaking and popping around the corners..) The 3/8” drive breaker bar makes a nice plug

wrench. (ror93-8.jpg)

I tilted the axle up at an angle to make filling easier

and put in about 2 ¾ quarts of lube..

(ror93-9.jpg)

It would

be very bad to have the flex brake line putting bending stresses on the steel

brake tubing (fatigue cracks eventually) so I flanged up a secure mount for the

axle end of the flex line..

(ror93-10.jpg... hose

clamps is good)

As the working

part of the day drew to a close I took the axle down from the hoist and made it

all ready to slide under Rustpuppy.. If it ain’t raining tomorrow it will be dirt in the

eyes day.. (ror93-11.jpg and

ror93-12.jpg)

More to

come..

Rick

Draganowski

(with

the weather change and the rains starting up again I am really creaking and

walking funny..)

Subject: Return of Rustpuppy report 94

Date: Saturday,

February 03, 2001 7:55 PM

After

the mild fit I had yesterday the rain stopped for about 2 hours in the late

afternoon. I forced myself to get

out and get going on the axle transplant project and stop whining and feeling

sorry for myself..

Anyway I

was faced with the problem of sliding the 320 lb axle assembly into place under

Rustpuppy. I used levers and

patience to skid it along an inch or so at a time.

(ror94-1.jpg)

I

crawled under one time to take a picture of the empty space where the axle

lives. GM painted stuff white

under there and most of the white paint is still there.. (ror94-2.jpg)

After

much levering and fooling around I got the axle close to where it should be..

(ror94.3.jpg, ror94-4.jpg) I

was having trouble standin upright and walking yesterday so I did 90% of this

part of the job sitting on the little red stool hunched forward..

I bought

a second floor jack from my local Ace hardware store. It looked pretty but is a malignant ill-conceived POS. It is one of those instant up one-pump

dogs and it is not reliable. It

only works about half the time you want it to and it is probably more than 5

times harder to lift stuff with than the old reliable jack (also bought at Ace

but about 6 years ago..) (ror94-5.jpg)

4000 lbs

my foot. It required a down

pressure of about 30 lbs to pick up 160 lbs (one of the few times it worked at

all) so with that ratio it would require a pump of 750 lbs to lift 4000.. I am taking it back and getting my

dough back ASAP..

And it

looked so pretty too.. Sigh.. (Chinese engineering at it’s best..)

Ror94-6.jpg

and ror94-7.jpg shows the axle waiting for final installation last evening..

Today

the weather and my physical challenges took a real turn for the better and

about an hour after noon a warm high pressure front came through and the rainy

stuff ended by two o-clock..

I dug right in on getting the front spring mounts bolted up loosely and

then farted around with the shackles trying to get everything lined up.

What a

bummer I found on the top shackle bushings from ESPO. Ror94-8.jpg shows a stock replacement rubber bushing from

NAPA sitting on top of the high zoot ESPO polyurethane job. It seems the ESPO bushing is exactly

0.025” bigger than the nominal 1.600 diameter of the holes in the frame. It would take a sledgehammer to get

them in and there is about 4” on the outboard side and 1 ½” on the gas tank

side clearance to work in.. BAH!

Why do

these things happen? I am

going to turn the polyurethane bushings

down in my

lathe to get them to the proper size but for now I went ahead

with the

stock replacement rubber bushings on the top mixed with the hard polyurethane

jobs on the bottom.. I

bet it will be a while before I get to that project.. Bah again!

Eventually

I got everything bolted in loosely and then put some weight on the axle and got

the shocks mounted. Then I

lifted the axle almost to the point of pushing Rustpuppy up off the frame

jackstands and crawled around tightening everything up. I will retorque the U-Bolts tomorrow

and put the locknuts on them as they are still a tiny bit from metal to metal

and the urethane will flow and loosen them up..

Ror94-9.jpg

shows the final state at the end of today’s 3 hour struggle..

(I am so

slooww!)

Now it

is time to hook up the brake flex line, bleed the brakes, install the

driveshaft, mount the wheels, and get

Rustpuppy

off of those jackstands and ready for a test ride!

And I

got to go to town for gasoline. I

drained all of the gas from the tank thinking I was going to drop it for

maintenance and changed my mind.

The gas I drained got used up by the riding mower (it didn’t need

premium) so a short roadtrip is necessary.. Mebbe tomorrow..

More to

come..

Rick

Draganowski

(still

walking funny but making progress)

Subject: Return of Rustpuppy report 95

Date: Sunday,

February 04, 2001 10:17 PM

Went to

bed early hoping for an extra long sleep but 730am found me wide awake and

eager to get back into the Rustpuppy axle project. I sat and took it easy while drinking my morning coffee and

annoying the list with morning messages.

Then the sun came out!

By the time I got out to the project area the sun was beating down. (Ror95-1.jpg) It was even shining on the axle a little bit.. (ror95-2.jpg)

I started

out by getting down and torquing the daylights out of the axle mount

u-bolts. Came close but still a

hair off of metal to metal contact so I put the double nuts plus internal star

washers locking devices on.

(ror95-3a.jpg)

I got

the flex line hooked up to the hard brake line and then I tried out the neat

Earl’s SoloBleed brake bleeders on the rear cylinders. They worked perfectly! It was a real pleasure doing the brake

bleeding this way. I monitored the

fluid level and made sure it was topped off. Excellent new adventure!

Then I

got the driveshaft ready to install.

I had it shortened 1.3” to compensate for the differences between the

7.5” and 8.5” axles. It took

longer than I expected to install the rascal because of trapped air in the

internal spline kept pushing it back out when I got into proper position. After much struggling I was able to pry

the driveshaft forward against the air pressure enough to snap the u-joints

into the saddles on the yoke..

I see what the little hole is good for in some of the driveshafts. Anyway with most of the weight off of

the rear wheels there is about 1 ¼” of clearance for the slipjoint. Looks the same as what it did before

actually..

Took a

little break after the driveshaft struggle and you can really see the sun

beating down on my work area..

(ror95-4a.jpg)

Then I

spent what seems like hours searching for the steel rod thingie which holds the

emergency brake cable on the passengers side.. Couldn’t find the damn thing. I got the emergency brake cables installed into the brackets

and hooked up the actuating wire.

Then out of desperation I flanged up a temporary cable hook thingie out

of some 1/8” steel rod I found laying around.. I bet the real part shows up in a couple days..

Then it

was time to get the rear wheels back on..

At long last! At first I

was fooling with my cross wrench but then the bright idea of getting out the

impact wrench saved me from myself.. I got the wheels back on (on the correct sides)

in a jiffy and it was getting close to the time of getting Rustpuppy back on

the ground.

First I

tested everything by starting Rustpuppy up and running forward and reverse

while Rustpuppy was securely up on the jackstands. Too cool! No

whining and the brakes even work!

I ran her up to about 70mph indicated and everything was smooth as

silk.. I had the driveshaft

straightened and balanced when it was cut and took the tires in for a

re-balance during this project..

Everything checked out good.

Next I

fooled around for quite a long time getting Rustpuppy down from the high

jackstands she had been on so long.

I had to go slow and careful since the stability goes south halfway down

and she is on a hill. She kept

wanting to fall off on the downhill side so I took a lot of precautions.

Eventually

she was on her own tires.. I

noticed the long traction bar bumpers were both touching so I think I will swap

back to the cutoff jobs..

Earlier

today I popped into town for gasoline so I put 5 gallons of premium in the

almost dry tank..

The

moment of first movement came!

Yowza! It felt

good.. Here is Rustpuppy posed

next to the Suburban and Yakima Sue.

Notice the new stock height springs moved the rear up about 1 ½” so

Rustpuppy is level fore and aft instead of dragging her tail..

I took

Rustpuppy out on the road for just a little bit. I went just a couple miles. On the way back I tested the positraction feature of the new

axle..

The two

wide black stripes in ror95-6a.jpg are a good testimonial.. (about 8” wide by 15 feet long,

and there are two of them! happy

happy, joy joy...)

Ror95-7a.jpg

shows the new stance that ol’ Rustpuppy has with them spiffy new ESPO springs..

A good

day. But, (why is there always a but?)

I got sunburned! In Oregon! In February!

I can’t

believe it.. And it was up to 67

degrees this afternoon..

More to come…

Rick

Draganowski

(making

Rustpuppy tracks.. nice

ones.. but my face feels hot..)

END OF

CHAPTER 10

![[ Back Button ]](../gif/t_back.gif)

![[ Go Home Button ]](../gif/t_home.gif)

![[ Next Button ]](../gif/t_next.gif)