Subject: Return of Rustpuppy report 9

Date: Friday,

March 24, 2000 10:59 PM

Due to an

illness in the family (ol’ Draganowski got an abcessed tooth) and the

excitement of Chuck Butcher’s amazing arrival with the Junkyard Dawg I have

neglected the on-going build up of Goody.

Fear

not, some work was accomplished. (and a couple of brain fart caused disasters)

First

the disasters. The first was minor

but annoying. While putting the

last valve in on the heads I managed to drop one of the keepers. I disappeared and could not be found on

the floor. Due to the ¾” crack

between the floor planks just below my workbench I guessed that it had gone

down under my barn (about 4 feet to the dirt below). I had some ratty old keepers salvaged from one of the

scrapped 305 motors I have, so the disaster was not serious, but I really

wanted to use the shiny new ones all the way through..

I

thought of a long shot solution. I

took a 5 foot length of brake tubing and taped my magnetic pickup tool to the

end of it. Then hoping against

hope (and common sense) I fished around blindly under the barn hoping the keeper

would show up on the end of the magnet.

This nonsense went on for about 5 minutes and I hauled up the magnet

hoping to find the keeper..

No such

luck. But I am a patient and

persistent man (some would say idiotically stubborn) and I tried again. Another five minutes of random area

sweeps in the dark underside of the floor. I hauled up the magnet and the keeper was there! Happy happy, joy joy.. A small victory but I am hoping it is a

good sign. This is the first

little widget I have ever recovered from the underfloor trap in the last 20

years..

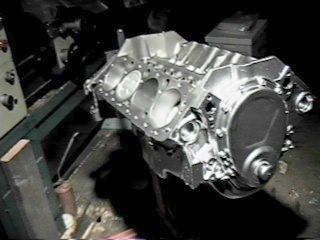

Now on

to the actual work. First I

carefully cleaned all of the old head gasket remains from the deck surface of

Goody. I used 220 grit wetordry

silicon carbide paper to polish the surface and remove any small

irregularities. The graphite

composition stock head gasket left a lot of crap on the surface but when I was

done it looked great (see ror9-1.jpg)

I had

planned to put on one head (the drivers side) and then check rocker

geometry. I have a crank turning

socket and when I removed the plastic cap off the end of the crank I found that

the second key (the one used to locate the vibration damper) was missing. It is always something. Nowhere in the Goodwrench Saga does CHP

mention that this part is missing on a crate motor. And the little bag of hardware that came with Goody

contained no Woodruff key.. Poop!

I

scrounged around for a while and located a rusty old 305 crank which had the

key. After removing it I carefully

installed it into Goody (messing up the paint on the timing cover, see

ror9-2.jpg) What a pain in the

butt.. But I am having fun..

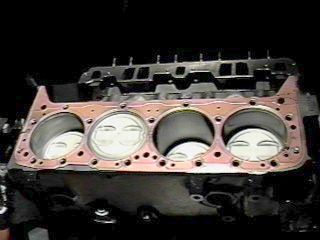

Then I

took the spring off of the number one exhaust valve and secured the valve with

a bundle of rubber bands. After

setting the head in place on the short block (on 3 layers of paper to get the

0.015 thickness of the gasket) I checked the rocker geometry. The exhaust valves have the most lift

so this was worse case. Pictures

ror9-3.jpg and ror9-4.jpg show the valve fully closed and fully open. No problems and the rocker stayed on

the center third of the valve stem and the slot is not binding. I expected no problems but it does no

harm to be sure.. Removing the

head and replacing the valve spring, retainer, and keeper took but a moment.

I have

heard from respected rodders that you should make the gaps in the keepers even

for some reason. Goody came with

them all (100%) jammed on one side with all the gap on the other.. Is this a valid concern or another

rodding urban myth?? Anyway I made

them all even..

Then I

move forward to putting on the first head. I carefully sprayed both sides of the Fel-Pro shim head gasket

with the CopperCoat and went to install it on the locating pins while the

CopperCoat was quite tacky.

Then the

Cosmic Brain Fart occured. It

seems that FelPro provides a odd shaped hole with a spring finger to accurately

locate the gasket on the pins. Not

wanting to mess up the coating I was being too delicate with the gasket and

naturally it fell to the dirty barn floor. I sat there blinking in disbelief as my first instinct (old

Space Center quality control reflexes) was to discard the now soiled (little

boogers stuck all over the tacky sealant) gasket. (25 bucks and much time just went sailing out the window)

I sat

for about a minute thinking of possible courses of action. Then I carefully (by the edges) picked

up the gasket and examined it. I

could see in the strong spotlight lots of boogers. But, if I take

my time and inspect carefully I could pick them (with an X-acto knife point)

off and give the gasket a clean bill of health..

About 20

minutes of intensive gasket-picking follows...

Then I

returned the rehabilitated gasket to it’s rightful position on the locating

pins.. (picture ror9-5.jpg shows

the gasket with the CopperCoat coating, cheating a little here as this is the

other head) The head followed and then I sat and replaced the head bolts after

coating the top third of the threads with the teflon paste sealer..

A little

time with my click type torque wrench and the head was down to stay.. My Chiltons sez 65 lbft but the senior

head builder on the internet sez 68 lbft of torque. I went through the torque sequence first at 30 lbft

then at 40 then twice at 50 then at 70 (my torque wrench is a little weak) for

3 times around.. Taking your time

here pays off..

After a

long pause (Chuck Butcher shows up with the Dawg!) I returned to replacing the

other head. With my experiences

with the first one as a guide nothing exciting happened and picture ror9-6

shows the current status of Goody with both heads in place. I stuck in some junk sparkplugs and did

some masking so I could finish the silver paint job on the long block.

More to

come...

Rick Draganowski

Date: Sunday,

March 26, 2000 9:03 PM

With the

heads in place and torqued down on the block it was obvious that the milling of

the heads created a problem with the front and rear sealing surfaces for the

valley area. They were sticking up

considerable. I did not want to

disassemble the short block to allow the surfaces to be machined so modifying

the brand new Edelbrock Performer manifold was the only solution.

A trial

fitting with gaskets showed the Performer hard down metal on metal both front

and back.. I had calculated that

at least 0.060 had to be removed from the bottom of the Performer to allow it

to fit properly. To be on

the safe side I set up to take 0.070 off. See ror10-1.jpg and ror10-2.jpg for the setup I used

for the flycutting of the manifold.

(tooling a little crude, just a fir plank bolted to the carb bolt holes

on the manifold and then clamped in the table vise., but I am a crude kinda guy)

The last

picture shows the Performer in place on Goody with gaskets and torqued

down. The feeler gauge in the

front indicates a minimum of 0.023 and the rear gap has a minimum of

0.033.. Close enough for

government work..

More to

come...

Rick

Draganowski

(plenty of

room for some RTV)

Subject: Return of Rustpuppy report 11

Date: Wednesday,

March 29, 2000 11:31 PM

While the

manifold was in place for the trial fitting I checked as well as possible the

alignment of the ports to the head.

With an inspection mirror and holding a little flashlight in my teeth

like a burglar I could see the top of the port on the drivers side rear top

plane. It looked like a good

fit. I took a picture of the

concentric location of the bolt holes in the head versus the holes in the

manifold.

The milling of the head came out excellently well. Then the manifold came off for masking

in preparation of painting.

The next

step in the buildup of Goody was to install the valve gear and adjust the

valves. See the finished job at

ror11-3.jpg. I used ½ turn of

preload on the stock GM hydraulic lifters.

I used the

¼ crankshaft rotation and follow the firing order technique. I found the job much more fun and easy

on the engine stand while comfortably sitting down rather than leaning over the

motor in Rustpuppy like the last time in “The Flat Cam Project.”

I filed

a little notch in four places on the crankshaft turning socket as a

reference.. (see ror11-4.jpg)

I was careful to gob a big blob of

the CompCams cam break in lube on the business end of each lifter as I

installed them.

The

pushrods seem strange to me. They

are straight heavy wall tubing with solid ball ends pressed into the ends. The are probably strong but they seem

quite heavy compared to the small block pushrods I am used to.

Then I

moved on to painting the Edelbrock Performer intake manifold. Oldsmobile blue.. The water pump, and stock valve covers

will be the same. I am going to

leave the Goodwrench decals on the valve covers and just mask them when I paint.

I

painted the vibration damper half silver and half blue so that if it starts

slipping it will be obvious.. I

also filed a notch in it at 30 degrees BTDC advanced to be able to check the

total advance without having to fix my dial back timing light. (lazy but effective) (see ror11-5.jpg and ror11-6.jpg)

More to

come..

Rick

Draganowski

From: Rick

Draganowski <dragan@harborside.com>

To: [NovaList]

<nova@seas.smu.edu>

Subject: Return of Rustpuppy report 12

Date: Thursday,

April 06, 2000 10:58 PM

After

making sure that the modified Performer intake manifold fitted properly up to

the milled heads on Goody it came time for the installation. It started well with the RTV going on

the water passages of the neato FelPro premium intake gaskets (with the little

metal inserts for the crossover passages and the teflon o-rings on the intake

ports). Then just as I

started to put the beads of RTV on the front and rear valley rails my damn tube

of RTV stopped up internally.

I was beginning to feel like the LesMiserabbit and out of desperation

snipped off one corner of the tube to get the RTV out. That worked in a messy way and I wound

up with a handful of RTV. The

beads were sloppy and uneven but I pressed on regardless.. I punched out the masking tape on the

ends to get a grip on the manifold and lowered it into place. It looked like a winner but I would

have been happier if more RTV squirted out from the rails front and rear.. Oh well.. If it leaks I will know why..

Then I

inserted the 1” stainless bolts for the manifold (the flanges on the Performer

are thinner than stock and the 1 ¼” bolts are a bit too long, Caution! 1 ½” bolts

used on the Performer manifold would rub on the pushrod on the center front

passengers side and center rear drivers side). I was careful to smear a bit of teflon paste on the four

center bolts to prevent the oil migration to the top of the manifold. I torqued the bolts to about 20 lb

ft. (just by feel) and the center

front one gave me trouble as usual since there is not enough clearance next to

the bolt head to allow the socket to go on very far.. But I muddled through.

Then I

put the spiffy 2-tone vibration damper on using the long bolt and stack of

washers technique.. I was careful

to put some grease on the surface of the damper the seal rides on so I would

not have a dry start messing it up.

Then the cad plated proper timing tab went on neatly.

I had

tried to get the studs which fit in the front flange of the water pump but NAPA

did not have them and could not order them. I got the pump from them but no studs. I am planning on running Goody on a

test stand in the shop and keep Rustpuppy in running condition so I can

position her for the motor swap when the time comes so I couldn’t swipe the

studs from Rustpuppy. I was

bellyaching about this to Tracy at NAPA and he suggested getting them out of

the 250 six laying around in the back of my shop. Duhh.. I never even thought of that. A few minutes work had them in

the proper pump..

I had

finished painting the genuine GM (rebuilt) water pump and it went on with some

2” stainless bolts and black RTV on the gaskets on both sides. The rusty studs looked a bit off but so

what..

I filled

the holes in the manifold and water pump with 3 brass ½” pipe plugs (they cost

2 bucks apiece! and they say there is no inflation..). Goody will not have a heater hookup.

Then It

was time to put on a oil filter. I

use and recommend the NAPA Silver filter as it is rugged, effective, and not

too expensive.. I installed

the oil filter adapter and relief valve assembly. (it didn’t come with Goody, I

got a used one for 10 bucks from Scott the machinist at NAPA) I had heard to

place the relief valve away from the block since it shrouds the oil passage a

little if you put it on the other way.

I oiled the gasket and spun on the filter and then took it back off to

verify the gasket sealing area. It

looked good so the filter went back on and hand tightened.

Then I

put the neat 50 buck rebuilt starter (also from NAPA) on with some new bolts (2

bucks each). I have another old

starter from the 400 motor but It is worth more than the 16 buck core charge so

I am keeping it as a spare.. (spare electrical stuff is good)

I

thought that before buttoning up the valve covers I would torque the head bolts

one more time. I am glad I

did. The CopperCoat sealer had

migrated a bit and relaxed the torque on five of the 34 head bolts. With the little flanged ½” head bolts I

could get a long 6 point socket between the rocker arms and torque the heads

without disturbing the valve adjustment.

Neat idea GM had.. (See

ror12-1.jpg)

Then the

valve covers went on (reusing the stock gaskets glued inside but putting grease

on them to keep them from sticking) with some stainless ¼-20 X 1” bolts and 4

of the extra heavy Moroso hold down tabs on the low sides and the factory tabs

on the high sides. They are gold

iridite and look a little out of place on the silver and blue motor but I like

them. At least they are not

chrome..

I

invested in another one of the splendid cast iron water necks and painted it

silver to contrast with the blue manifold.. More RTV and stainless bolts and it was in

place..

The last

picture show the current status of Goody.. I expect to have her running on the test stand soon..

Rick

Draganowski

(still

having fun..)

Subject: Return of Rustpuppy report 13

Date: Sunday,

April 16, 2000 11:39 PM

This is

a mixed bag of odds, ends, and waiting for parts. Since I have become determined to run Goody on a “Test

Stand” in the shop it has been a battle of details to get Goody ready to run

and a place for her to run on. I

am determined to keep Rustpuppy running to the last moment to allow driving her

to the motor transplant area so that left me short a lot of bits and pieces.

First I

needed to get the waterpump turning.

I scrounged a top pully from the 250 six and the crankshaft pully from

the 400 motor. Then I was faced

with connecting them with a belt.

It has to be the exact size as there is no adjustment since I am just

running the two pullies. I needed

a 34” 7/16” wide belt. My NAPA

informed me that they only had metric belts now and they are not really the

same sizes. I got a belt that was

supposed to be 34 1/8” but they must measure it in a strange way as it came up

short. The actual exact

measurement was 33 7/8”.. Pressing

on regardless I cut and spliced (by sewing with stainless wire) an old fan belt

I had scrounged off the shrinking 250 six. It came out exactly right and looks like it will last as

long as it is needed..

I need a

radiator for the stand and “lo and behold” resting on the passengers seat in

The Junkyard Dawg is a splendid 3 core copper and brass Nova radiator in

excellent condition. I never

expected this..

(thanks again Chuck)

A bit of cleaning with a wire brush and straightening out of a few fins

and it looks almost new..

I had

hastily put the cast iron water neck on (with a little RTV) and after thinking

about it for a day or so realized that I had completely forgotten about the

thermostat. This kind of stuff is

happening more and more to me..

Hmmm..

I had

the old thermostat from Rustpuppy left over from when I did the “Flat Cam

Project”. First a little cleaning

with a scraper and wire brush and then the neck had to come off and clean up

the old RTV and then it was in place with new RTV.

I had

ordered a chrome distributor hold-down from Northern Auto Parts as I was sure

that I did not have one. I thought

of the trouble I gave Rob over his and thought about ways of removing the

chrome. But when I was scrounging

around in boxes for the thermostat I ran across a stock distributor hold down

clamp. I swear I have never seen

it before and have no idea how it got into my junk.

It

cleaned up nice with the wire brush and left a permanent impression of itself

on the shop floor outlined in silver spray paint.. Just before I put it on Goody with a ¾” long stainless bolt

I looked at the hole where the distributor goes and a cold chill went down my

spine. So I first carefully

covered the distributor hole with a double layer of masking tape as I know as

strange as things are going it was a sure thing that I would drop something

down there.. Then the clamp

was in place.

I had

originally planned to use the ordinary motor stand as the nucleus of the “Test

Stand” but found that it interfered with the starter motor after I (with a lot

of trouble) pulled it off the 400 motor in the corner and left the 400 sitting

on it’s pan. Regrouping I first

thought of welding up a special rig to mount Goody. The area I need cleared away for this type of project was a

total disaster would require help and a couple of days labor. So I fell back to ordering the “Deluxe

Motor Stand” from Jeg’s which

mounts only to the front motormount pads and leaves the rear of the motor free

to mount a transmission if you want.

It came on Friday and it is a splendid piece of equipment. Heavy and well engineered and it will

show up prominently in the pictures in the next report.

I have a

tach (Sun Super Tach II) on the way with a bunch of other odds and ends and

already have the Autometer mechanical water temp and oil pressure gauges for

the “Test Stand” console. I will

have a hand throttle and ignition and starter switches as well. All in stock and just need to come

together.

Due to a

brainfart of large proportions I lost track of the bag which contained the

7/16” by ¾” long dowel pin packed with Goody and intended for the crankshaft

locating pin location. I finally

scrounged one from Scott the machinist at NAPA (he pulled one out of a scrapped

crankshaft for me)..

I have

the flexplate from Northern and neato ARP 12 point mounting bolts. First I chamfered the mounting holes on the flexplate as ARP

demands as there is quite a fillet under the bolt heads. Then using some of the leftover

CompCams Moly lube on the bolts I torqued them sequentially and sneaking up on

the final number to 65 lb ft..

I was a little pissed to find the “locating hole” was a ½” hole and fit

loosely on the pin I had gone to quite some trouble to get.. Wish I would have known that I

could have left the damn pin out..

I will

be bolting on the 2200 rpm stall converter to act as a flywheel on Goody and

have a neat set of ARP bolts for that.

I have to

come up with the spring mounts for the test stand (going to use Goody’s stock

springs) and the control console.

Also I have a set of 2” ram’s horn manifolds and I have to cobble up an

exhaust system. There is some good

looking pipes and a muffler under the Junkyard Dawg that looks like it can be

pressed into service.

There is

a lot more and the next report will have pictures..

More to

come..

Rick

Draganowski

(wonder

where those pins are??)

Subject: Skinning knuckle

Date: Monday,

May 01, 2000 7:54 PM

I was

slowly putting the cheapo 2200 stall converter on Goody so she would have a flywheel

to run with on the test stand. I

was using the crappy ½” long 3/8”NC grade 5 bolts provided with the 97 buck converter by the

“ProMotive” torque converter people (has anyone ever heard of these guys?) and

the wrench slipped off.

The

angles were wrong and there was only about half of the wrench actually on the

bolt.. Anyway my favorite

knuckle (right hand, index finger, second knuckle) intersected the little

pointy part of the block bellhousing flange and peeled back a flap of knuckle

meat almost big enough to make a sandwich with.. Mebbe with mustard.

I was

planning on writing up the pretty long story of “The Return of Rustpuppy report

14” but since I have a splint on

my right index finger my typing skills are in the toilet..

Lots

more to come when I can touch type again..

Rick

Draganowski

(Goody is

bouncing on springs now..)

Subject: Home of Rustpuppy and The

Junkyard Dawg

Date: Sunday,

May 07, 2000 9:24 PM

I told

Mikael these would show up this weekend..

This is

from ½ mile up the hill above us..

Rick

Draganowski

Subject: Rustpuppy from afar..

Date: Sunday,

May 07, 2000 9:28 PM

Telephoto

pics of Rustpuppy taken from the hill above.. Medium magnification and full magnification..

The

grass is growing up all around her..

Sigh... Everything takes

too long..

Rick

Draganowski

(Goody

report real soon, I promise..)

Subject: Return Of Rustpuppy report 14

Date: Monday,

May 08, 2000 10:43 PM

This

episode is titled “Distributor Madness”.

Actually

it is not the whole story on the progress report on Goody, it is just a little on getting the

Proform Distributor in proper tune to work on Goody.

I am still

typing impaired so this is mostly a visual report.

First I

checked the end play. I was

amazed to find a whopping 0.060..

Too much.

A moments work with a pin punch and the roll pin out and the biggest spacer in the distributor shim kit (0.050) in place between the thrust washer and the drive gear.

There is a dimple machined into the gear which lines up

with the rotor. It can go on wrong

if you are not careful. A recheck

of the clearance and it is right at a happy 0.010..

Then on

to the vacuum can. The stocker in

the “Proform High Performance” distributor is a stupid 25 degree unit.. Can you say ping? All wrong again. The vacuum can in a HEI moves about

1/8” for every 10 degrees of crankshaft advance. I had the Accel adjustable job already set up at 10 degrees

so in it went..

Then on

to the centrifugal advance. Nice

looking powdered metal weights (first I have seen) but really heavy

springs.. Bet the total advance

would not be in till about 4500rpm

like stock again. I wonder

about the coil voltage since everything else is wrong for performance.. Sigh.. It was cheap though..

At the time.. I pawed

through the leavings in the Moroso advance curve kit and found Too Strongs and

Too Weaks. Just Rights seem

to be in Rustpuppy’s old distributor..

Hmmm.. What to do..

Mixed

one Too Strong with one Too Weak and will bet that it is close to Just Right...

Buttoned everything up and it is ready to go into Goody

tomorrow..

More to

come..

Rick

Draganowski

Subject: Return of Rustpuppy report 15

Date: Wednesday,

May 17, 2000 10:15 PM

Rustpuppy

got moved today. Some precious (to

me) seat time. Poor

Rustpuppy has been languishing for months with the grass growing up around her. (ror15-1.jpg)

Today I

got in and after enough cranking to prime the Q-jet she started right up. Still sounding good except for “the

knock”.. I made a big circle

in the yard and parked her into position where the motor transplant will take

place. You can see my shabby ol’

Barn/Workshop, Rustpuppy, the Junkyard Dawg, and my scabby looking Suburban in

this picture..

And the

last one is of the Suburban..

Every time I look close at that old land battleship I have

images of a 3” lowering job, about a 4 inch section out of the body at the

beltline, and a 4 inch top chop..

Then with the simple addition of some Kandy Apple Blue paint, and a 502

crate motor turning a TH400 tranny the vision is complete... Mebbe someday..

Anyway

the next report will be on the Return of Rustpuppy and the Goody Test Stand

(just inside the door of the Barn)

Real life keeps interfering with my Nova projects though...

Rick

Draganowski

(too

many projects, not enough time, never enough money..)

Subject: Return of Rustpuppy report 16

Date: Tuesday,

May 23, 2000 12:08 AM

Progress

has been made on the test stand for Goody. I flanged up a wooden cradle which bolts to the bottom of

the neato premium engine stand that Jeg’s sells. Under the cradle out of sight are four of the stock

intake valve springs removed from Goody during the cam transplant. It makes a nice bouncy cradle to absorb

the motor vibrations. I also

cobbled together an instrument panel with a new Sun Super Tach II (the one with

“Magnetic Suspension”) and a toggle switch for the ignition and a push button

for the starter. Under the

switches is a mechanical oil pressure gauge and temp gauge set. (nice Autometer

gauges from Northern Auto Parts)

The 20

buck (from Jeg’s) pre-oiler is well worth the dough and should provide a

lifetime of service.

I hooked

up the oil pressure gauge making sure to use sealant on the pipe threads and to

properly torque the teensy fittings which crush to the teflon tubing.. You have to feel the brass

ferrules crushing but not go too far.

Experience is the best teacher here. (my first mech exposure was repairing lawn mowers and other

equipment for seventy-five cents an hour back when I was a kid.. and they used

tons of them teensy lines, copper not plastic though)

Then the

pre-oiler was in and my little (but damn noisy) electric drill in place. I ran the drill watching for leaks and

monitoring the oil pressure.. It

slowly came up to about 30 psi..

Cool! It was the first time

I have ever done this.. (never

cared this much about a motor before either) I ran it for about 5 minutes and will run it for 10

minutes more tomorrow when I find my nice quiet drill.. Then it is time to put in the

distributor and wire everything up..

The harness for the instrument panel can be seen bunched up behind it.

I got a

new set of Walker Dynomax JetHot coated headers (about 210 bucks from Jeg’s)

for Goody and will flange up some kind of exhaust system to spare Marie (my 75

year old neighbor) the insane noise of running with open headers.. I plan on salvaging the old

single exhaust system out of the Junkyard Dawg and plumb the output of the

headers down into the single turbo muffler.. Quieter is better for now on the test stand..

Much

more to come...

It won’t

be long now..

Rick

Draganowski

(having more

fun than should be legal..)

END OF

CHAPTER 2

![[ Back Button ]](../gif/t_back.gif)

![[ Go Home Button ]](../gif/t_home.gif)

![[ Next Button ]](../gif/t_next.gif)