Subject: Return of Rustpuppy report 17

Date: Thursday,

June 08, 2000 10:22 PM

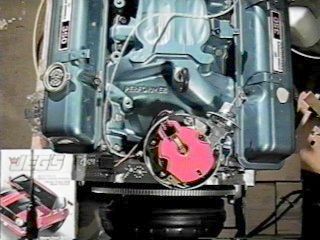

This part

of the adventure was getting the distributor in and set for the initial startup

of Goody. I have Goody set on TDC

firing stroke of number one. (ror17-1.jpg)

Then a surprising thing happened when stabbed the

distributor randomly just to get it in.

It went in all the way!

Sort of winning the oil pump drive shaft lottery with the first

ticket.. Cool.. Greg Colletti in his “Rebuilding Your

Engine” video from KLK Productions shows his technique of rotating the oil pump

shaft to position the rotor in the correct place without using anything other

than the distributor. You pull it

out, rotate it 180 degrees and then reinsert it. It catches the driveshaft and rotates it half of a

tooth. Then by repeating the

pulling, rotating, and reinserting as many times as necessary the direction of

the rotor turns one tooth for each two stabs counterclockwise.

My

random lucky insertion was about 4 teeth off so eight pulls and stabs had the

rotor pointing in the direction of number one sparkplug..(ror17-3.jpg)..

Then I set the initial timing by eyeballing the reluctor

points to give me about 8 degrees of advance. (ror17-5.jpg) It looks like the rotating part of the

reluctor is about 1/16” clockwise from the fixed part when it is close to

right..

Then I

locked down the distributor using the stock hold down bracket with the spiffy

slotted hole and no chrome..

Rotating the motor till the reluctor points lined up exactly showed just

about exactly 8 degrees BTDC on the initial timing.. (closer than I expected..) (see ror17-6.jpg and

ror17-7.jpg) The last

pic shows how the distributor looks with the cap on.. (ror17-2.jpg)

More to

come..

Rick

Draganowski

(taking

my time cause too much else is happening around here..)

Subject: Return of Rustpuppy report 18

Date: Friday,

June 09, 2000 6:48 PM

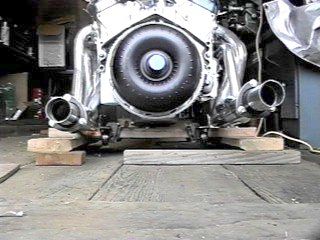

The long

awaited Dynomax ceramic coated headers arrived. It was amazing the difference it quality between the 210

buck Dynomax ceramic versus the 140 buck el cheapo FlowTech ceramic headers I

bought for Rustpuppy 3 years ago..

The ceramic is much thicker and looks much more like chromium plating

than the dingy old ones (which are rusty beyond hope)..

A trial

fitting showed that they interfered with my test stand on both sides. Moving the rear support forward

provided enough room for the passenger side to clear. But it took some serious chiseling to get room for the

drivers side.. (see ror18-1.jpg, ror18-3.jpg, and ror18-4.jpg)

Hmmm.. The driver side collector is too low and

the passenger side collector is too high.. On average it is just right.. (see ror18-5a.jpg)

And the passengers side is pointing to the right instead of

straight back.

(see

ror18-6.jpg)

But

problems are meant to be solved and they still look damn good to me...

Next on

the agenda was putting the premium NAPA silicone plug wires on. I used a bunch of garbage bag twisties

to hold it together while I puzzled over which length wire went where.. ( I will be putting the ty-raps on

tonight..) (see ror18-8.jpg)

I have a

set of Accel universal wires (bout 24 bucks from Jeg’s) but I took one look at

the Accel stuff and gave it a pass.

You need a special crimper, the terminals looked pretty cheap, and the

bright yellow color looked kind of stupid to me.. The subtle gray with black boots of the NAPA pre-terminated

ready to go jobs suits me fine..

Anyone want the Accel universal plug wires? Cheep...

Much

more to come...

Rick

Draganowski

(had a

rough week with too much work and not enough gumption or something..)

Subject: Return of Rustpuppy report 19

Date: Sunday,

June 11, 2000 11:26 PM

While

taking a break today and thumbing through the Jeg’s catalog, (not much plot but plenty of details) I

came across a page showing shims for moving the distributor up to the stock

location after head milling. Then

the thought hit me like a ton of bricks.

With the modifications I have made to Goody the distributor was sitting

about 0.085 lower than it should be.

It seemed OK when I installed it and this issue never penetrated my old

brain till I saw the shims in the catalog..

“Seemed

OK” just is not going to be good enough..

Hmmm.. What to do. I will be firing up Goody as soon as

the new mufflers (2 ½” Dynomax Super Turbos) show up so there really is no time

to order in..

I

decided to flange up some homemade shims.

An old VHS tape box provided the neat 0.050 cross-linked polyethylene

material and a pair of iris scissors and some time provided the rest.. (see ror19-1.jpg)

Pulling

the distributor out was just the work of a moment, then in with the 0.050 shim

and an additional 0.030 gasket and the distributor went back smoothly pointing

exactly where it started from and 0.080 higher in the saddle. (see ror19-2.jpg)

I pulled

the rotor and fine tuned the 8 degrees BTDC initial timing and then buttoned

her up.

More to

come...

Rick

Draganowski

(details is

important..)

Subject: Return of Rustpuppy report 20

Date: Tuesday,

June 13, 2000 9:10 PM

Details,

details.. I went to put the

adaptor into the drivers side head for the water temp sensor. Ha! It turns out that the header on that side has to come off

first, which means the tyraps on the spark plug wires have to be cut.. And so on... I had the adaptor sitting on the bench next to where I

did the porting and thought about putting it in way back then.. but

didn’t.. duhh.. (ror20-1.jpg)

I had salvaged

the oil dipstick out of the 400 motor and a little cleaning up and a coat of

Self-Etching-Primer (my standard

coating for everything from now on..) it went in fine.. I have heard that there is

supposed to be an o-ring between the little flangie thing and the top of the

block but have never seen one. Is

that correct? (ror20-2.jpg)

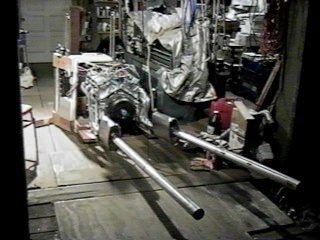

I have

cobbled up wooden feet for the 3-core radiator (from the Dawg) and got the

hoses and clamps on. Then I though

about cooling air. I plan on

running Goody for quite a while on the stand so the radiator definitely needs a

fan of some kind. I had an old

industrial grade window fan in a stand (looking rusty but runs good) laying in

the back of the back area and dug it out.

I have it pulling air in reverse flow through the radiator.. It should work since there is no real

load on Goody.. (ror20-4.jpg and

ror20-5.jpg)

I took

one last pic of Rustpuppy’s Target Master motor as it sits today. It will never look like this again.. (ror20-3.jpg)

The last

pic shows Goody in the foreground and Rustpuppy in the background getting ready

for her transplant..

More to

come..

Rick

Draganowski

(two steps

forward, one back..)

Subject: First Spiderometer, now

Arachtach..

Date: Wednesday,

June 14, 2000 11:07 PM

Last

year I was complaining about the damn spider which had infested the speedometer

on Rustpuppy so it could not indicate faster than 60mph..

Well I

have had the Sun Super Tach II mounted on the console for Goody’s test stand

for about 3 weeks and today 12v was applied for the first time. The needle swung to zero as advertised

for the magnetic suspension indicator but I noticed a strange movement inside

the tach.. The attached picture

shows the intruder.. It’s web is

so fine that the needle broke it but I am sure it will keep trying..

Damn, it

is always something weird..

I think I have a plan on evicting my bothersome arachnid. The spider has an instinct to

spin a web near a lighted place which attracts prey.. I taped an opaque disk over the face of the tach with a

strong light shining on the little hole in the rear where the spider came

in. I expect by tomorrow it will

move to where I can smash it with the wires.. Ha ha ha ha...

(maniacal spider killer laugh..)

You can

see the little pest in the picture.

Spider on the left and it’s nasty little shadow on the right..

Rick

Draganowski

(infested in

Oregon..)

Subject: Die spider die!

Date: Thursday,

June 15, 2000 9:51 PM

My

theoretical solution to the tiny spider infesting my new Sun Super Tach II did

not work at all. I had failed to

take into account that spiders have even more patience than even I..

So I

took serious steps. The front

bezel is held by four little plastic lugs snapping into four little slots. I carefully pryed with a screwdriver

and eventually after about 10 minutes of fooling around popped off the bezel

and glass.. The nasty little

spider came out on the center of the glass on the inside and before she could

scamper off, the end of my right index finger spelled doom to her and all of her

wicked plans. (which including immobilizing the needle in my brand new 58 buck

tach..)

The

picture shows the body (looking rather shapeless) about in the center of the

glass... Ha!

hahahahahaha!!!!!!!

(maniacal laughter...)

It took

twice as long to get the freshly cleaned bezel snapped back into place as

taking it off. (you gotta pry in three places almost at the same time, like a

puzzle..)

Rick

Draganowski

(Rick 1,

Spider 0..)

Subject: Goody runs tonight... (I hope)

Date: Monday,

June 19, 2000 9:25 PM

I am

going through the last checklist before starting Goody on her cam breakin

maiden run..

It feels

a little like before the launches at the Space Center..

The

Astronaut’s prayer..

Dear

God, please don’t let me foul

up... (the actual word used was not foul)

Rick

Draganowski

(more to

come, I promise..)

Subject: Re: [nova] Goody runs

tonight... (I hope) (YES!)

Date: Monday,

June 19, 2000 10:08 PM

Goody

started up like a dream (cranked for less than 12 seconds).. She sounded good. Throttle responsive (almost too

responsive).. Temp went to 180

degrees and stayed there (180 degree thermostat) Oil pressure steady at 48lbs.. Vacuum at 18 inches..

Puked a

pint or so of water when I shut down since I started up with no radiator

cap. The only other issue was the

Dynomax Super Turbo’s started smoking like mad after about 10 minutes of

running.. They are coated with

some kind of clear varnish or something..

Stunk me out.. I shut down

and will run no more tonight as It is 10pm and I have to think of my elderly

neighbor lady..

Up close

and personal she sounds gooooood!

Rick

Draganowski

(happy

happy, joy joy)

Subject: Return of Rustpuppy report 21

Date: Tuesday,

June 20, 2000 7:43 PM

As most

of you know from the posts yesterday Goody is up and running on the test

stand. I had very little time to

do anything except “real projects” today so not much has happened. I looked into the task of relocating

those stinking Dynomax Super Turbo’s to the end of the exhaust pipes instead of

the collector adaptors. I figure it

is cooler there and the mufflers would be outside instead of inside the

shop. I had puttied the connection

between the collector adaptor and the inlet of the mufflers with ultra high

temp RTV.. (hah!)

The

modest temperatures at this location (about 400-500 degrees F) turned the red

ultra high temp RTV into a lubricant..

I could just wipe it off after separating the joints.. So much for hype.. (see ror21-1.jpg)

I have

transplanted the super tuned (by my humble standards) Q-Jet from Rustpuppy’s

knocking motor to Goody last Friday during the G2K transits.. It is working fine but the idle is a

little off because of the much bigger cam in Goody..

Anyway

after finished the “must be done” project I started Goody up to show off to my

electrician’s helper and associate who worked with me today. He was properly impressed but during

the short run I noticed a liquid dripping out in the right front of the

motor.. I looked down and

was horrified to see fuel dripping in a stream from the fuel pump onto the shop

floor... I immediately shut goody

down. (probably took about .7 seconds

from cognition of fuel leak to switch off..) I instructed Dave to withdraw and armed myself with

the industrial sized universal dry chemical fire extinguisher 3 feet from Goody

at the door of the shop. No more

excitement followed, thank God..

Whew!

I am in

process of disassembly and inspection to determine what went wrong with the brand

new Carter performance fuel pump or perhaps the hookup. It is strange since the leak only

occurs with the motor running and when the motor is stopped the pressure is

held in the line to the Q-Jet..

There is a slight head of pressure at the inlet connection but the leak

stops when the motor stops so that joint is ok.. Another strange thing is that it did not leak

yesterday.. Hmmm.. I had packed the pump with

grease.. Maybe the gasoline

finally got through.. Hmmm..

I think

it is just a screwed up fuel pump from the factory.. Just my luck..

More to

come on this.. (I got 2 known good

fuel pumps to substitute..)

If this

fuel leak had occured in Rustpuppy after installation of Goody it could have

lead to a serious car fire..

Rick

Draganowski

(test stands

is good)

Subject: Return of Rustpuppy report 22

Date: Sunday,

June 25, 2000 7:39 PM

When I

tried to demonstrate Goody running on the test stand to a friend I noticed fuel

dribbling from the bottom of the fuel pump. Rather than scientifically deducing what exactly was

leaking (after wasting time and discomfort changing the new Carter pump with a

messed up used job) I shotgunned the problem and swapped out the pump (with a

16 buck NAPA job) and the stock steel line which leads to the Q-Jet. I used brass fittings designed for this

purpose with a taper seat on the threaded end and a hose barb on the other (5

bucks at NAPA) Then two 100%

stainless hose clamps and a piece of 3/8” fuel line. (ror22-3.jpg and ror22-4.jpg)

No more

leaking at all and I am happy with that..

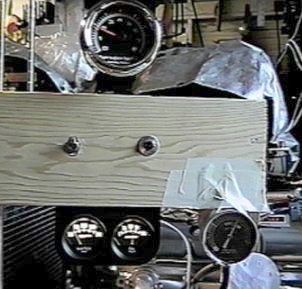

Ror22-1.jpg

is what the test stand looks like now that it is 100% operational.

Ror22-2.jpg shows the instrument console while Goody is running about 2000rpm.

Note the oil pressure is half way between 50 and 75 lbs on

the Autometer mechanical gauge. I

am going to use nothing but straight 30w oil in Goody (with mebbe a smigen of

Marvel Mystery Oil)

Today

after what seems like many hours of important honey-do’s I got a bit of time on

“The Project”. Off came

Rustpuppy’s rusty old hood clearing the way for the coming transplant..

See

ror22-5.jpg and ror22-6.jpg...

More to

come, even audio...

Rick

Draganowski

Subject: Return of Rustpuppy report 23

Date: Saturday,

July 01, 2000 9:21 PM

Now that

Goody seems to be running happy on the test stand the process of Rustpuppy’s

motor swap is on the front burner of Nova work.

I picked

away at the old motor clearing away the distributor, alternator, power steering

pump, and fuel pump to clear the way for removal. (ror23-0.jpg)

There is

plenty of room to work in the 4th gen (Disco) Nova’s engine

room.. I wonder if I need to pull

the crankshaft pully... That

may give more clearance during the removal..

Note the

ordinary corks sealing the ports on the power steering gear to keep stuff

out.. Hydraulics is picky about

dirt and stuff..

I spent

the last couple of hours jacking and messing around to get Rustpuppy up high

enough to wedge my fat old bod under to do the necessary disconnections.. Ror23-1.jpg shows the driver’s side

header with the lowest pipe flattened pretty bad.

I may have bottomed just a few times (mebbe a hundred)

since the road here is pretty bad..

The passenger’s side is high and outside just like the new headers which

is encouraging as the stainless exhaust pipes may not required much mods (if I am lucky, none.. fat chance..)

See

Rustpuppy in position for her heart transplant.. (ror23-2.jpg and ror23-3.jpg)

More to

come.

Rick Draganowski

(getting

anxious)

Subject: Return of Rustpuppy report 24

Date: Sunday,

July 02, 2000 10:02 PM

Today I

managed to get some of the nasty dirt in your eyes and aches in your arms stuff

done on Rustpuppy. It is amazing

how nice ol’ Rustpuppy looks on the underside as there is hardly any rust

there. All the floor pans, subframes,

and other stuff still looks good.

It is the damn salt in the air settling with the dew every night which

is doing the destruction from the top down..

Anyway,

I pulled the rear universal bolts and dropped the end of the driveshaft. I will leave it plugged into the tranny

till I find the bucket for the leak that pulling it will generate. I still have cramps in my

shoulders from working overhead.

Rustpuppy is only high enough to just clear my fat old cripple bod so

the working conditions under there are miserable..

Then I

attacked the header adaptors.. Not

too bad, as I used stainless nuts

and bolts for the installation three years ago and this end of Rustpuppy is

higher.. It still took 40

minutes for them 6 bolts though..

The installation of the exhaust system was well done by my exhaust guy

as the gaskets were perfect with no leaks..

I can

pull the drivers side header with no problems (just take no. 5 spark plug) so

out it came. It looks pretty gory

on the bottom (not hundreds but thousands of bottomings) and I will send

pictures in the next report.

The passengers side header will come out next time as I have to

disconnect and pull the starter first. Maybe tomorrow..

Progress

is slow but even getting a little done makes me happy..

Also I

am starting up Goody and running her a little every day to keep my attention

focused..

No

pictures (not that much to see this time..)

More to

come..

Rick

Draganowski

(still have

dirt in my left eye)

END OF CHAPTER 3

![[ Back Button ]](../gif/t_back.gif)

![[ Go Home Button ]](../gif/t_home.gif)

![[ Next Button ]](../gif/t_next.gif)