Subject: Return

of Rustpuppy report 41

Date: Thursday,

August 17, 2000 9:06 PM

Not a

lot of Nova work but plenty of “real” work done today. I had an important meeting in town and

also managed to pick up two sheets of ½” plywood for the much needed stable

floor for the Goody installation.

It is the damndest thing though.

Modern 21st Century ½” plywood is 15/32” thick.. Is everything going to hell? (I am an old lumberyard employee from

back in 1960-61...)

On the

Nova front I managed to put the TCI Breakaway torque converter on and have all

in preparation for the tranny/motor mating tomorrow.. Tom’s advice about the two thunks was the ticket and the

second one was difficult to find.

I almost pushed the tranny off the stack of boards onto my foot.. But both of the thunks eventually

showed up.

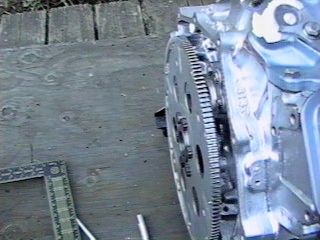

Ror41-1.jpg

and ror41.2.jpg shows the male and female parts of the operation. (can’t help thinking about sex for some

reason)

I

measured the distance from the bellhousing mating surface of the block and the

torque converter mounting pads and came up with 15/16” which gave me a ball

park target to shoot for with the mounting. (sex again!)

(see ror 41-3.jpg..)

Ror 41-4

shows the torque converter happy and snuggled in properly with a distance from

the mounting ears to the bellhousing plane of 1 1/16”. This puts a 1/8” gap between the

converter and the flexplate after the tranny is mated to the motor.. (more sex?

Draganowski, you are a dirty old man..)

More to

come..

Rick

Draganowski

(measuring

is good)

Date: Sunday,

August 20, 2000 8:00 PM

Today

was the docking maneuver day.

(gonna try not to use any sex terms) I got Goody on the hoist and close to the tranny and then

wrestled the guidepins and converter pilot into place manually by moving the

transmission. (ror42-1.jpg is the

starting point)

The

converter could spin freely and was about 1/8” from the flexplate bolt pads

after the six transmission mounting bolts were tightened. (ror42-2.jpg)

I put in the neat ARP 12 point converter bolts and torqued

them to about 45 lb ft. The

standard bolts are supposed to be torqued to 30 lb ft but I figured the ARP

high zoot jobs could handle 45 easy..

GM says to tighten the bolt which goes into the radially slotted hole on

the flexplate first or you get an Aren style vibration. Then the other two which have the slots

in the tangental planes..

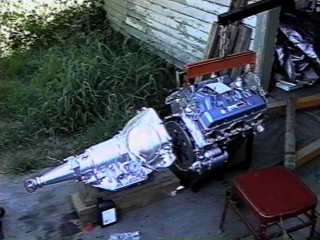

Ror

42-3.jpg shows Goody at working height all together (including the nasty black

tin flywheel cover thingie) and getting close to installation.

Ror 42-4

shows Goody sneaking up on Rustpuppy at a stealthy level..

More to

come..

Rick

Draganowski

(It won’t be

long now..)

Subject: Return of Rustpuppy report 43

Date: Monday,

August 21, 2000 8:29 PM

The

opening picture is taken from under my “Shade Tree” which provides shade and

the name of my auto shop..

You can see Goody eagerly waiting and Rustpuppy looking helpless..

(ror43-1.jpg)

A quick

note on the Junkyard Dawg. When

Dave was working on Patches I had him spend an hour cleaning up all of the

surface rust dings and scrapes on the Dawg and primer and paint them. Since he was using blue, blue it

was.. ((ror43-2.jpg)

Details

need attending to prior to installing Goody so today was a detail day. I had the hole left when I pulled out

the heater/airconditioner from Rustpuppy plugged with aluminum flashing and

aluminum tape. Hardly an elegant

solution. I wanted to keep access

to the hole in the firewall as it makes torqueing the rear header bolt on that

side much easier.

First

thing was looking for the piece of aluminum (1/8” x 8” x10 ½” ) I had cut for the

firewall door about 2 years ago.

After wasting about 45 fruitless minutes I spent the next 25 minutes

making a new one. (bet the old one

shows up tomorrow.. bah!)

Then the hole in the middle and the piece of 2x2 for a

toggle and a stainless bolt, washer, and nut and the door was done. I put a double layer of dense

foam weatherstripping around the hole and the door was on in a jiffy.. (would have been a lot easier with a

helper..) (ror43-3.jpg,

ror43-4.jpg, ror43-5.jpg and ror43-6.jpg)

Now on

to the ProMatic installation..

More to

come..

Rick

Draganowski

Date: Monday,

August 21, 2000 9:30 PM

It is

Pro-matic all the way with this report.

I wanted to get the initial messing about with the tranny done prior to

installation.

Ror44-1.jpg

shows the neat box the Pro-matic shifter came in. The first jarring note was the sticker on the plastic

console thingie.. (ror44-2.jpg) I

wonder what the out-of-work moldmakers and machinists in this country are doing

these days..

Then I

was amazed by the motly collection of bracketry and widgets in the kit. It seems Hurst is trying to be all

things to all people..

(ror44-3.jpg) You

know I resent having to pay for all that junk just to get what I need. (what I need is in ror44-4.jpg)

The next

thing I noticed is that the steel plate the TH350 shift arm is made from is too

damn thin. As a result the nut

securing the arm bottoms on the shaft and the arm wobbles and flops too much

for precision shifting. I

added a ½” ID washer and a 3/8” washer to properly clamp the arm so it does not

wobble. This is not a good

sign. I thought that Hurst knew

how to make these things..

Sigh.. The cable

bracket needed the spacers to line up with the arm properly and the extra long

bolts they provide are ¼” too short..

Details, details..

(ror44-5.jpg)

More to

come..

Rick

Draganowski

(picky old

engineer)

Date: Tuesday,

August 22, 2000 8:46 PM

Today’s

hour or so was spent on the second phase of the Pro-matic installation. First I

figured where I wanted the thing to be.

Then I felt around through the hole and encountered the spot welded in

reinforcing channel right were the rear bolts go.. It is always something.. (ror45-1.jpg...

note the tranny eye’s view of “The Hole”)

It says

in the instructions that you_MUST_ mount the shifter on a flat surface and if

you bend the mounting ears down it voids the warrantee and causes the shifter

to foul up and jam. Since I am a

tall dude I decided to use a custom made 5/8” thick aluminum spacer. (7075T6 aged 20 years and harder than

mild steel) (note drilled and

ready spacer ror45-2,jpg and 1 ½” hole for cable) That surface will stay flat..

Then the

shifter in place and the 4 bolts wrestled in. It was pretty neat since “The Hole” allowed me to put the

bolts in from inside Rustpuppy with a moderate amount of contortions and

groveling.. (ror45-3.jpg)

The last

picture (ror45-4.jpg) shows the shifter bolted in snug and ready to go..

Then I

sat in the motorless Rustpuppy and played with the shifter. (like a little kid)

More to

come..

Rick

Draganowski

(Goody will

be home very soon..)

Subject: Return of Rustpuppy report 46

Date: Wednesday,

August 23, 2000 7:52 PM

Serious

and important work interfered with Nova work today but I did get just a little

in. The most excellent Ben

Meissner (Ourstanding Artist and Designer) took pity on my tale of woe relating

to using *&^%#%^#*& truck motor mount brackets on Rustpuppy and sent me

a pair off of his 74 parts Nova.

They arrived today and I only had time to get them and the tranny

dipstick tube cleaned up and painted.

Ror46-1.jpg

and ror46-2.jpg show the small but important difference between them. Also the truck bracket is thicker

metal.. I went crazy trying

to make the wrong ones work and am glad to never have to face that again.. (at least until the Dawg goes back

together..)

Ror46-3.jpg

shows the painted brackets and tranny tube and ror46-4.jpg just the new (to me)

brackets.

You will

notice the tab which bolts to the bellhousing is missing on the tube. I just clamp it in place with a hose

clamp.

I

shortened the truck tube about 4 inches to fit it under Rustpuppy’s hood and

hope I got the length of the dipstick right. From the bottom of the rolled bead which seats on the top of

the transmission casting to the end of the dipstick when it is fully in is 2

7/16”. Does that sound about right?

More to

come...

Rick

Draganowski

Subject: Return of Rustpuppy report 47

Date: Thursday,

August 24, 2000 8:22 PM

Painfully

slow progress but some tiny progress today. After an urgent trip to town wasted most of my Nova time

waiting in line and listening to Aerosmith at a stupid road construction mess..

While in

town I picked up a replacement O-ring for the tranny dipstick tube. (after 23 years they lose some of their

ringiness..) So all I had

time for was getting the custom 2 piece tube in with it’s custom hose clamp and

custom RTV at the pulled out spotweld holes..

Then I

addressed the motor mount brackets.

I checked first for the depth of the threaded holes in the block and

found a couple that could not accept a 1” bolt with two washers and the

bracket.. So I rounded up a

half dozen ¾” bolts. I had

problems in the past with the skinny pasty Goodwrench boys not tightening these

bolts enough so I gave them about 38-40 lb ft..

And that

is where she sits tonight.

Just moments away from actual installation..

I just need

one unbooked afternoon and evening..

Rick

Draganowski

(just four

crummy little hours..)

Subject: Return of Rustpuppy report 48

Date: Friday,

August 25, 2000 9:02 PM

A Nova

work window about 2 ½ hours long opened up today. My first instinct was to go like crazy and just get Goody

installed and worry about the

details later. After a few

minutes of feverish preparation reason intervened.

My

training was to never let emotional bias interfere with technical

decisions.. And here I was rushing

off in an emotional frenzy..

After leaving the scene to think, I realized that now with Goody on the

hoist at a comfortable working height is the best time to attend to as many of

the little details of motor installation as I could. This would avoid the nasty crawling under the car with dirt

in my eyes business as much as possible..

So that

is where the 2 ½ hours went today.

First thing was modifying and installing the detent cable bracket. Those

stupid and no longer used ears had been bothering me for 5 years. I even put the recommended Tyrap on the

detent cable where it crosses the dipstick tube to keep it constrained. (ror48-1.jpg and ror48-2.jpg)

Then it

was press on to putting on the finishing touches and installing the starter

heat shield I designed and made last summer. I used a 100% stainless 6 ½” hose clamp. The shield itself is made from two

layers of aluminum flashing with 4 layers of extra heavy duty aluminum coated

Kraft paper inside. It is trimmed

with slit and RTV’ed on vacuum hose to protect the wiring. (ror48-3.jpg and ror48-4.jpg)

Then the

balance of daylight was spent on rehabilitating the steel tranny cooler lines

and the transmission modulator line. Steel wool and brush on black acrylic enamel for the

cooler lines and the neat silver NAPA Commercial paint (as used on Goody and

the tranny) for the modulator line..

More to

come... for sure...

Rick

Draganowski

(the

only time I know of that NASA forced a launch for political and emotional reasons was the Challenger.. Something we never would have done back

in the days of Apollo... how times

change, sigh...)

END OF

CHAPTER 6

![[ Back Button ]](../gif/t_back.gif)

![[ Go Home Button ]](../gif/t_home.gif)

![[ Next Button ]](../gif/t_next.gif)