Subject: Return of Rustpuppy report 49

Date: Saturday,

August 26, 2000 9:59 PM

A four

hour Nova time window opened up today.

The weather was great, my physical problems at a minimum, and eight

months of impatience driving me..

A good day..

The

first picture shows Goody picked up about 10” higher than needed to test the

capabilities of the medium short settings on the hoist. (ror49-1.jpg)

Rustpuppy

waiting anxiously at the end of the plywood runway...

The next

seven pictures show the painfully slow process of getting Goody into position

to drop onto the motor mounts.. (ror49-3.jpg through ror49-9.jpg) Due to the rough ground and uneven

grade it took about 3 hours of my work window to horse the hoist along about an

inch at a time by prying with a 2x3...

But I was patient and careful and it worked out.. I had to add another

sheet of plywood to get the runway long enough.. More groveling on the ground and pounding nails under

Rustpuppy to secure the two sheets together..

Finally

right at the fall of night and the end of an exhausting but exhilarating day. Am I tired!

GOODY

WAS HOME! (See ror49-10.jpg)

The

proper motor mount brackets from Ben Meissner worked perfectly and the through

bolts slid (with the aid of a little hammer) right into place..

It took

a little pulling and jerking and wrestling with Goody to get her to drop into

place but It seems to always require some physical strength to get things

together..

More to

come...

It won’t

be long now..

Rick Draganowski

Subject: Return of Rustpuppy report 50

Date: Sunday,

August 27, 2000 9:17 PM

A bit of

a low impact day today due to physical challenges caused by overextending myself

yesterday but important progress was made.

First

thing was the under Nova groveling related to getting the tubular crossmember

and transmission mount installed.

Taking my time and doing most from a comfortable laying down position it

went in slick an pretty. (see

ror50-1.jpg) I even got the

speedometer cable installed and had a few thoughts of getting the driveshaft

in.. (Naaa... tomorrow mebbe)

Things

look much better down here and now I am ready to finish the installation of the

Pro-matic shifter cable and stuff..

(ror50-2.jpg) It is a shame

I had to mar the pretty silver paint by jacking under the tranny pan.. Oh, well. Dings and scuffs happen when we move heavy stuff around..

I also

(before I could forget and have Goody fall out on the road) put the nuts on the

motormount through bolts and torqued them down.

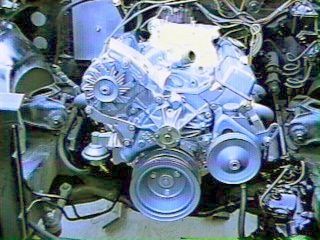

Finally

there is a smiling picture of Rustpuppy showing off Goody in the

daylight.. (ror50-3.jpg)

More to

come..

Rick

Draganowski

(snapping,

popping, creaking, and groaning..

but having fun!)

Date: Monday,

August 28, 2000 9:13 PM

Spent sitting

time cleaning up the rusty driveshaft and painting it black and getting the

crankshaft pulley looking decent.

The

biggest task was getting the passengers side header in.. It was a bit of a hassle with the

starter on the motor but it

threaded up from the bottom.. This

is the one that really don’t match the Flowtech collector location.

Ror51-1.jpg

shows graphically why I wanted to have “The Door” instead of closing the

firewall hole permanently..

Makes the last header bolt easy instead of a PITA..

Ror51-2.jpg

shows the header in place torqued down with the plugs installed.. Nice..

Ror51-3.jpg

shows just how much the exhaust pipe comes up short.. The Stainless 409 alloy adaptor looks rusty but it is

just discoloration and would polish up like a mirror.. (Not me!) The rest of the exhaust back to the Super Turbos is 304

alloy and does not polish well but does not discolor like the 409 alloy. I really wish that it fit.. Sigh..

More to

come..

Rick

Draganowski

Subject: Return of Rustpuppy report 52

Date: Tuesday,

August 29, 2000 7:44 PM

I have

been noticing that the motor is offset slightly toward the passengers

side. More in the rear than in the

front.. I wonder if that was to

get the driveshaft aligned better or to balance the weight of the driver.. Hmmm... See ror52-1.jpg and ror52-2.jpg.

I was

itching to see if the driver’s side header would line up. The differences looked minor with the

headers off. But a few minutes

work with the special little 3/8” wrench for them neat stainless ARP header

bolts and I jumped under to see..

Nope.. Not as far off as

the passengers side but way off..

Oh, well..

(ror52-3.jpg and ror52-4.jpg)

I figured

a way of making a semipermanent hookup between the existing pipes and the

header collectors while doing chores and thinking last night. By using the cheapy 2 ½ collector

adaptors provided with the Dynomax headers.. Here is how. I

will cut the adaptors length down so they snugly fit into the bell of the

existing adaptors and bolt them to the headers with threaded rod. Then I draw the existing pipes tightly

against the stubs sealing pretty good..

That would last for quite a while till I can get my exhaust guy to make

a proper fix..

Then I

spend a little while cleaning up an painting the alternator and power steering

pump and brackets..

(ror52-5.jpg,

ror52-6,jpg, and ror52-7.jpg)

I have a

lot of important work to do so the Nova time ended early today..

More to

come..

Rick

Draganowski

(fog came in

and it is dank!)

Subject: Return of Rustpuppy report 53

Date: Thursday,

August 31, 2000 8:26 PM

We had a

cold front yesterday and the nasty wet misting fog at 57 degrees is here.. Ror53-1.jpg shows the view as I went

out for some Nova work today..

Brrr.. I am

physically challenged by this kind of weather change so I did not expect to get

much done today..

Anyway,

all that was accomplished was the installation of the cable for the Pro-matic

shifter. Right off the bat I had

nothing but trouble. I had

carefully cut the 1 ½” hole exactly as the instructions. But I did not think that moving the

shifter up 5/8” of an inch with the flat spacer would call for the hole being

somewhere else.. Duhh.. My trusty manual sheet metal nibbler

made short work of extending the hole to where it was really needed.. Slower than the air powered

one but a lot more accurate..

Ror53-2.jpg shows the shifter in first gear (where the initial

adjustment was made) and the extended hole..

(Note

the nice silver transmission showing through “The Hole” like a misplaced piece

of the Starship Enterprise hidden behind a hatch on the Mining Ship Nostromo..)

The

underside picture shows the cable hooked up to the shift arm. I manually put the transmission in

first and then adjusted the mounting nuts and pivot pin to where it would just

drop into the hole in the shift arm.

(ror53-3.jpg)

The last

picture, ror53-4.jpg shows a little of the cable routing. It doesn’t seem to come anywhere near

the headers.. Good..

Then I

sat in Rustpuppy and played with the shifter.. I notice that the 1-2 shift detent and the N-R shift detent

did not feel as crisp as the others..

To test the accuracy of the detent mechanism in the shifter versus the

detent mechanism in the transmission I did the following. First I removed the cotter key at the

pin where the cable attaches in the shifter. Then shifting through all the gears I pulled the cable off

the pin and tried to slip it back on..

The results are as follows.

1st-

lines up perfectly - (this is

where the adjustment was made) 2nd- shifter 0.008” to 0.010 short of

lining up.. (felt mushy when

shifting to second)

D- lines

up perfectly

R-

shifter 0.005” to 0.008” short of lining up.. (nother mushy detent)

P- lines

up..

It seems

that there is some inaccuracy in the design or perhaps wear in the tranny

detent..

I

probably will work just fine but it just feels off to me..

Rick Draganowski

(picky old

engineer)

Date: Friday,

September 01, 2000 8:57 PM

The cold

drippy fog lifted today but I had important meetings in town so I only got a

few minutes of Nova time..

I mentioned earlier that the “Dueling Detents” problem I am having with

the Pro-matic ratchet shifter could probably be fixed by inserting a bit of

“mechanical latency” into the system.. (slop or play to you)

So the

first thing was to slide under Rustpuppy and take out the clever fix I had

worked out for the wobbly shift arm “perceived problem”.

Then

back in the cockpit I tested all functions on the shifter.. It passed with flying colors.. Every detent was crisp and the cable

could be pulled off and replaced on the pin in all positions with no problems

as now each detent is free to do it’s job.. Happy ending..

There

was still a bit of time before dark so I addressed the driveshaft

replacement.. It went on in a

jiffy and looks much better with its coat of shiny black paint..

More to

come this fine weekend..

Happy

Labor Day..

Rick

Draganowski

(laboring on

the Nova!)

Subject: Return of Rustpuppy report 54a

Date: Sunday,

September 03, 2000 9:37 PM

A new

day and the cold rain and fog just a memory. (ror54-1.jpg)

I decided to

press on with getting the headers flanged up to the too short exhaust

pipes. After careful measurements

I came to the conclusion that both sides were exactly 1 ½” short of hooking

up. So my plan of using the

cheapy collector adaptors as spigots fitting into the collector adaptors on the

pipes came into play.. The overall

length of the adaptors was 3 inches and the taper of the stainless collectors

used up exactly one inch. So ½”

had to be trimmed from the adaptors..

The only way of getting a clean straight cut which would seal was to

flange up a mounting jig and use the Bridgeport with a slitting saw.. (ror54-2.jpg, ror54-3.jpg and ror54-4.jpg)

Right at

this point we had a power failure for the whole local area.. So Nova work stopped dead. I set up the generator and ran the

power cable the 150 feet to hook up to Deloris special environmental trailer.. That was a tussle and took a lot of the

starch out of me.. Anyway the

power company got the problem fixed in about an hour or so things could go back

to normal.. I just sat and

did some painting while the power was out..

Then I

cut up some 3/8” NC threaded rod for the fasteners which will make it

work.. (Ror54-5.jpg)

I was pooped and it was getting damp and dark but I

managed to get the passengers side hooked up to prove the principle.. Looks almost permanent, don’t it? (ror54-6.jpg)

And

first thing tomorrow I will get the drivers side in (ror54-7.jpg) and then get

back on installing the accessories for Goody.. It is getting closer to seat time!

More to

come..

Rick

Draganowski

Subject: Return of Rustpuppy report 55

Date: Saturday,

September 02, 2000 8:11 PM

Since it

is a holiday weekend the weather turned dead against me. Cold rain (57 degrees) wind, lightning

and thunder.. Nice..

Nova

work went on between the showers of cold rain. I got the fuel pump in and found with the front bumper off

and the radiator support bar and radiator gone it is almost a pleasure. You can just reach in and do

it.. Having the motor at TDC of #1

compression stroke helps here too..

Then

just before the next deluge started I installed the modified Proform

distributor I am using in Goody. I

was careful to return Goody to TDC on the #1 compression stroke after messing

about with torque converter bolts so the distributor just fell exactly into

place..

Then I

had to put the tarp back over Goody as the cold rains continue..

Tomorrow

is another day..

More to

come..

Rick

Draganowski

Subject: Return of Rustpuppy report 55a

Date: Monday,

September 04, 2000 8:54 PM

Laboring

on Labor day but the vast majority of it had nothing to do with Nova

work.. Anyway I got the missing

coupling flangeup onto the exhaust making it ready to rock and roll..

Then

uncovering Goody which had been lurking under a silver tarp for a few days I

found something nasty but perhaps fitting.. The damn mice had been under the tarp looking for a home and

pooped all over the top of Goody..

Those little black thingies are mouse turds.. (ror55-1,jpg)

Then I

managed to get the spark plug wiring harness with neat clear distributor cap

(so you can see sparks and stuff turning in there) into place.. (ror55-2.jpg)

I am

still a little worried about old number six spark plug boot as there is a scant

1/8” clearance between the boot and the header no matter how the wiring is

run.. I hope that it will be

enough but doubt that the high temp red RTV will last and I need to get a

replacement boot for that plugwire.. We will see..

Then

Goody’s dipstick went into place..

I am thinking of pulling the tube out a little and putting a touch of

RTV on it to keep it from leaking..

If I remember..

Last

detail for today was fastening the motor ground wire onto one of the head

accessory holes by the firewall with a stainless steel bolt..

I spent

a few minutes sitting in Rustpuppy looking at the dash and trying to figure out

where and how to mount the instruments

(big gauges and a 120 mph speedo)

It was seat time after a fashion as I could sense that the real thing

was getting close.. I

got a feeling the dash pad mounting hardware is all under the dash somewhere

and probably will not take it off since I am not going to crawl my fat old body

on the floor trying to get under there..

Can it be taken off without the crawling around part? Distructively is OK..

More to

come..

Rick

Draganowski

(soon now..)

Subject: Return of Rustpuppy report 56

Date: Tuesday,

September 05, 2000 9:25 PM

Got a

two hour window for Nova work today but it was late and half of it had to be

after dark with a droplight stuff..

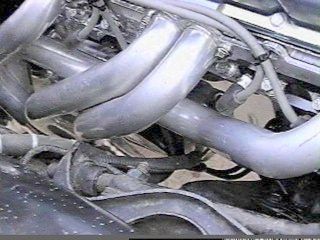

First off I got a decent picture of the exhaust “Probe and Drogue”

docking system (stolen from NASA) with both pipes hooked up.. (ror56-1.jpg)

Rustpuppy

has a one legged 3.08 ratio 7 ½ inch ring gear differential.. (Scott assures me

that the 7.625 job never got into a Nova..) The most excellent Ray Buck assures me that the little

guy is strong enought for moderate street fooling around. (no slicks or

positraction)

Has any

one else got a good word about this spindly looking rear end? The Junkyard Dawg will probably

end up with the 7.5” rear end out of Yakima Sue so it looks like there is not

going to be a 8.5” ten bolt in my future.. If I do need one some day what do they cost in an “honest”

junkyard? (ror56-2.jpg)

Then I

concentrated on getting the power steering pump and hoses back on and hooked

up. By the time I got to the

hose fittings it was dark and I had a hell of a time getting the fittings to

screw properly into the steering unit..

But after much fumbling around, spilling of fluid, and trying different

angles they came together.. (even

torqued them properly with a tubing wrench.. ) (ror56-3.jpg)

More to

come..

Rick

Draganowski

(getting

closer.. every day... closer..)

Subject: Return of Rustpuppy report 57

Date: Wednesday,

September 06, 2000 9:45 PM

Pressing

on with the installation of accessories on Goody to get on the road ASAP.. I started with some

last minute painting.. Got a heavy

coat of flat black spray paint on the new 2-core radiator Rustpuppy will be

using and painted the motor side of the fan.. (leaving the other side black as you cannot see it much..)

Then I

crawled under and checked and tightened the header flangeup studs and put a gob

of high temp RTV on each of the 18 nuts in the assemblies to keep them from

vibrating loose..

Then I

progressed to getting the alternator brackets and alternator on.. I am using the alternator off of

Rustpuppy’s original 250 six as the ball bearing in the truck alternator is

starting to sound gritty..

Ror57-3.jpg

shows the nice truck brackets and 10SI alternator in place..

Then going around the other side I find that the damn six

alternator is assembled with the connector and terminal 180 degrees away from

the v8 job.. (ror57-4.jpg) So just when I thought I was

getting somewhere I have to fix something..

Then I

tore the alternator apart and readied it for assembly in the right way.. Ror57-5.jpg shows the explosion and

ror57-6.jpg and ror57-7.jpg show a 0.050 Allen wrench holding the brushes in

place to allow assembly.. Then

after adding a blob of grease in the roller bearing it was together matching

the old truck v8 alternator..

(ror57-8.jpg)

Then it

was deja vu with the alternator back in place.. (ror57-9.jpg)

But with a big difference..

It ain’t upside down in the back now.. (ror57-10.jpg)

I got

the rear end of Rustpuppy off the jack stands and back with her tires on the

ground getting ready to get the ramps out tomorrow.. (ror57-11.jpg)

I

realized when I encountered the alternator assembly problem that I was beginning

to stress myself out with impatience and stopped everything and just sat and

looked at Goody for a while.. Due

to my health problems it is important to keep stress down to an absolute

minimum.. So I took my

time getting things in order and started enjoying the work again.. Whenever Rustpuppy runs will be soon

enough..

Tomorrow

is another day..

More to

come..

Rick

Draganowski

Subject: Return of Rustpuppy report 58

Date: Thursday,

September 07, 2000 9:09 PM

Pressing

on in a calm quiet way, before I took Rustpuppy off of the jackstands and

ramps, I just sat and stared at her and thought. Then it came to me..

The starter wiring was not hooked up yet! So it was crawl back under and try to figure a way to do it..

There is

only room for one hand in the area and it is impossible to see what is going on

so it took quite a bit of fumbling around to get the wires on and the nuts in

place. Then it was a challenge to

tighten the nuts.. After what

seemed like days under there it all came together.. In ror58-1.jpg you can see the starter lurking under them

headers somewhere..

Ror58-2.jpg shows where old number six boot is getting

toasted.. I have it flanged in

with a Tyrap and plenty of high temp RTV.. But I really need to get a skinny boot for this

position..

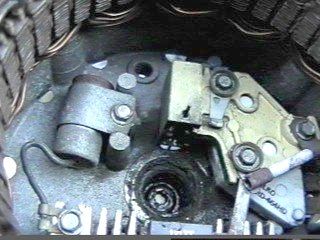

Back to

the starter wiring, ror58-3.jpg is an underneath shot showing how the terminals

are not visible.. Lots of

scratching around to get it together..

After

that fun job was over I horsed around and got Rustpuppy off of the jackstands

and back on her wheels..

Yipee! A big step is made

toward seat time!

Notice

without the front bumper, hood, radiator, and other odds and ends ol’ Rustpuppy

is way nose high.. She normally

sits a little high in the front (because the stock rear springs are sagging

about an inch or so.) but this looks strange.. By the way, that strange smear on the door

there is moss and algae growing on the north side of poor Rustpuppy.. Mebbe even some small lichens

too.. Sigh.. It has been a long time..

Then

with Rustpuppy at a comfortable working height I got the belts on and adjusted

and the fan on. It is a big 7

blade truck fan with a thermostatic clutch.. (ror58-5.jpg)

More to

come..

Rick

Draganowski

END OF

CHAPTER 7

![[ Back Button ]](../gif/t_back.gif)

![[ Go Home Button ]](../gif/t_home.gif)

![[ Next Button ]](../gif/t_next.gif)